utils : utils

- testing utils and simulations

- transformation tests : transform_test.py

- PI current synthetis : pi_torque.ipynb

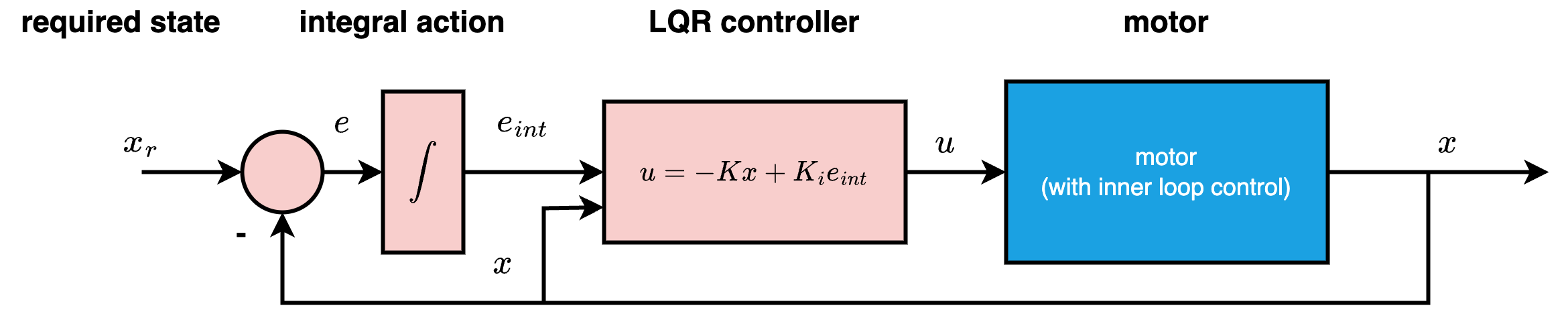

- LQR synthetis : lqr_design.ipynb

- requires LibsControll

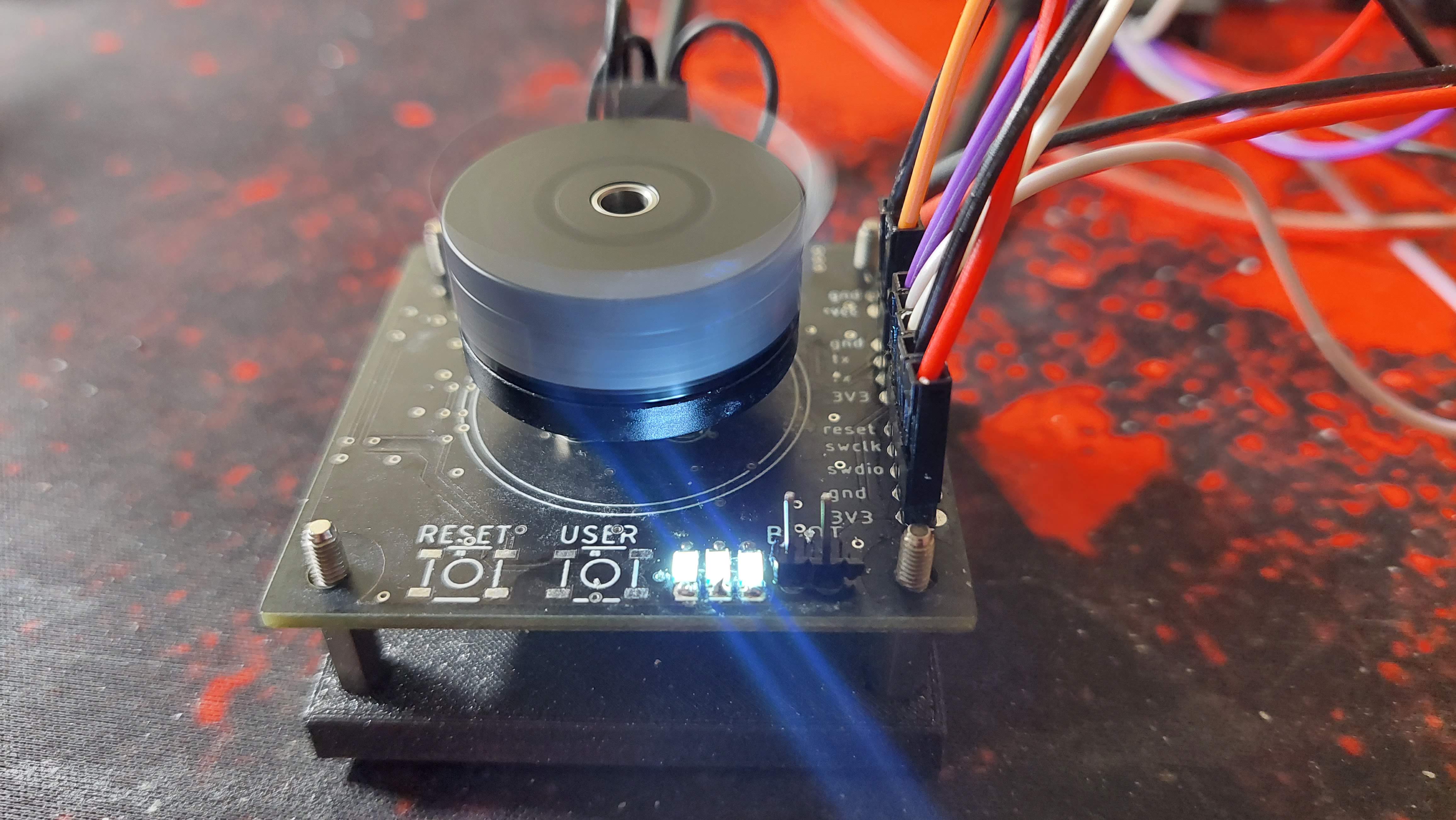

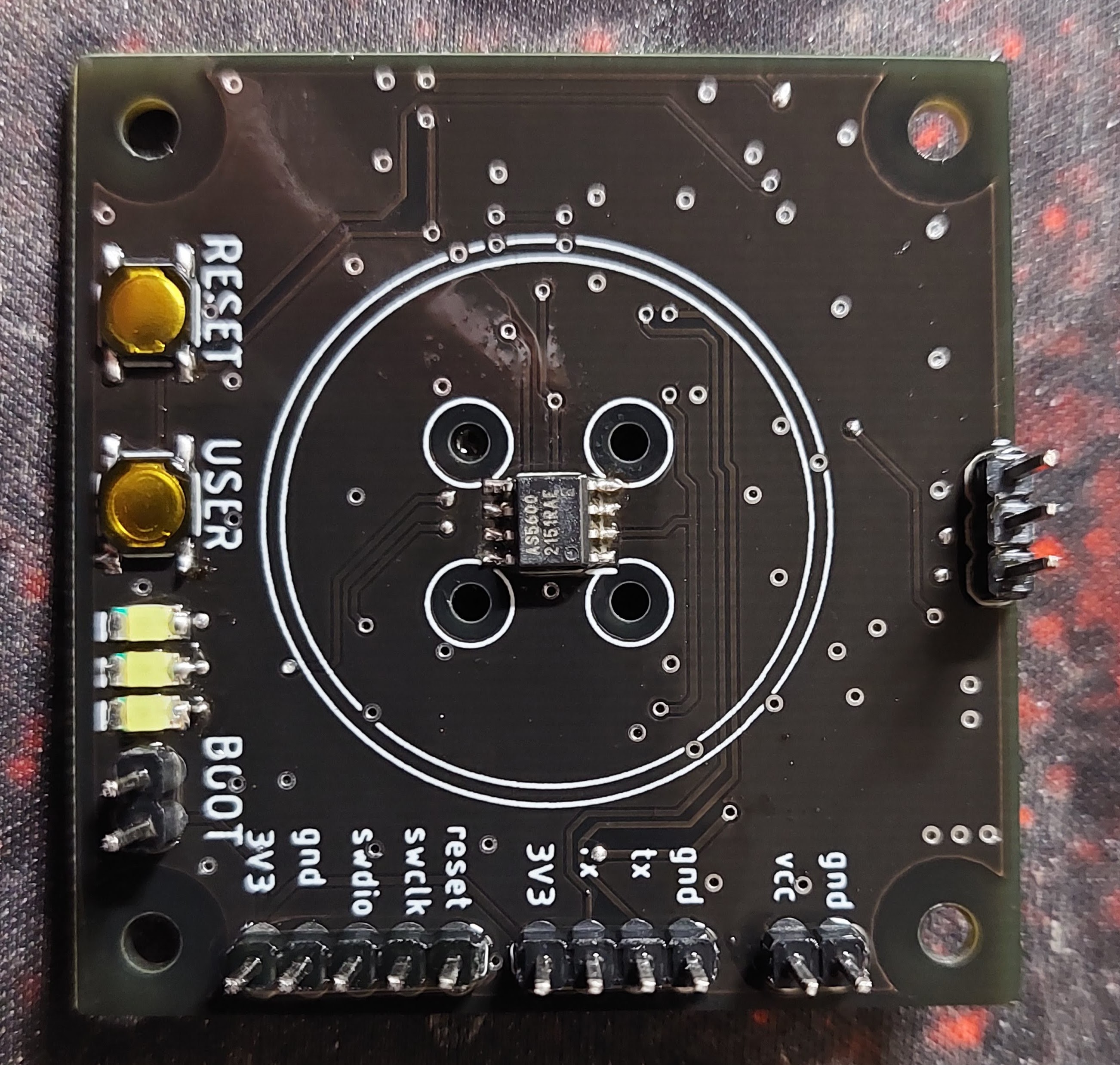

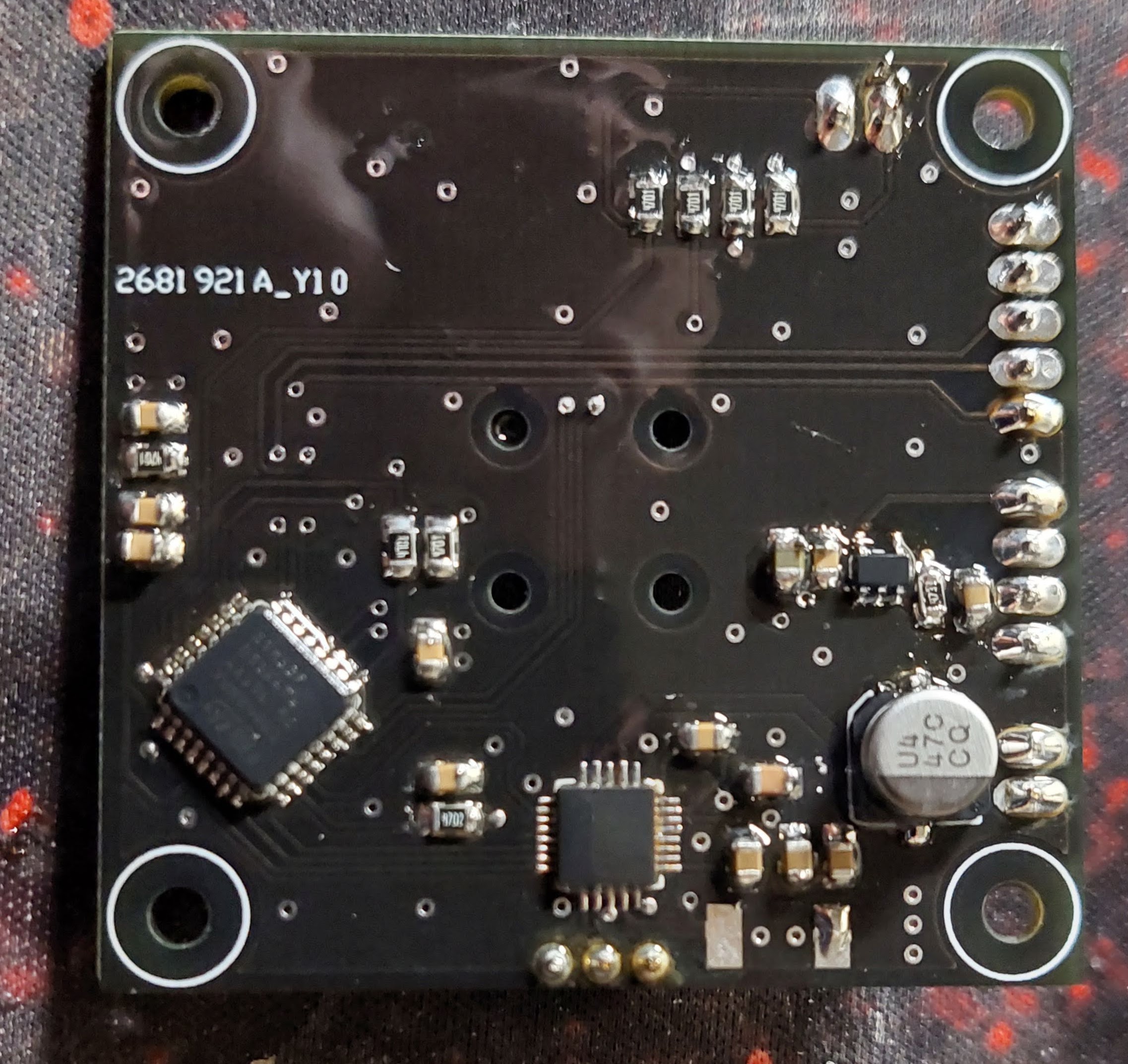

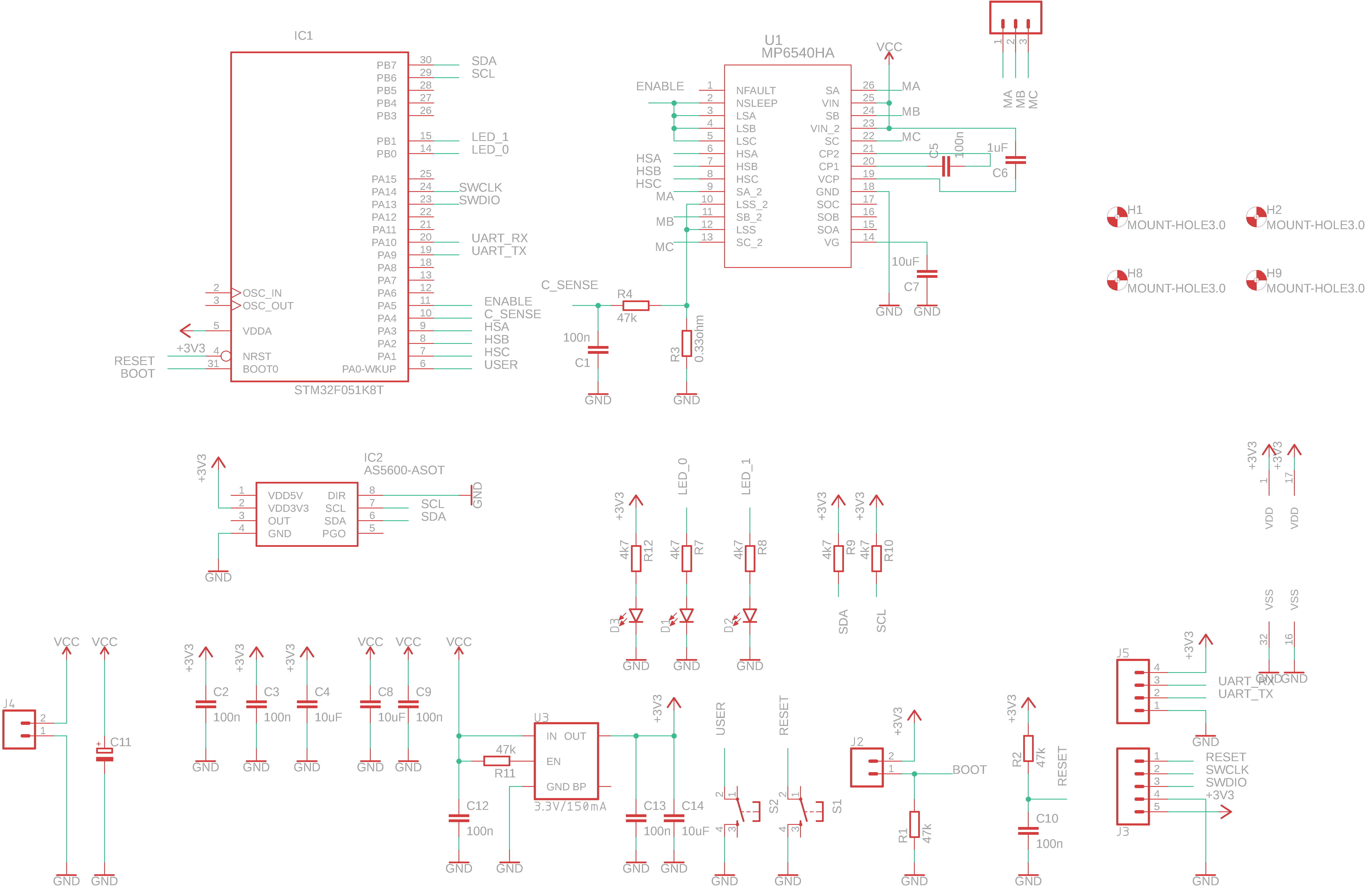

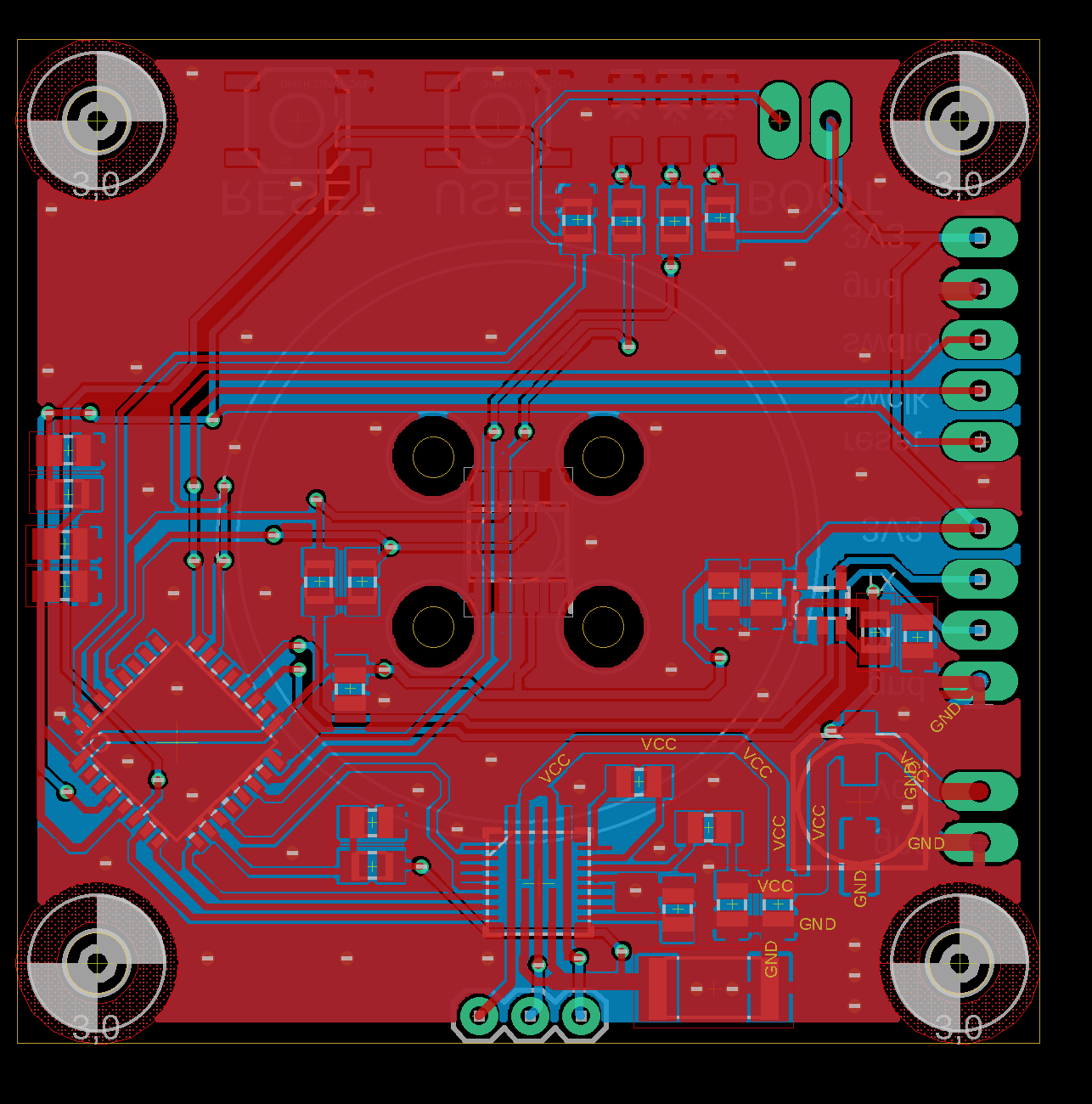

hardware : hardware

-

eagle files

-

3D priting parts (jig for magnet centering)

-

IMPORTANT - in schematic is wrong MP6540HA, correct is MP6540H (pwm only driver with enable)

-

MCU : stm32f051, arm cortex m0, 48MHz

-

3phase driver : MP6540H (DONT MP6540HA), 5A, 50V

-

encoder : AS5600, 12bit, i2c

firmware : firmware

- main code for stm32f051

- core is in user folder

- see motor.cpp and motor_control.cpp to understand all details

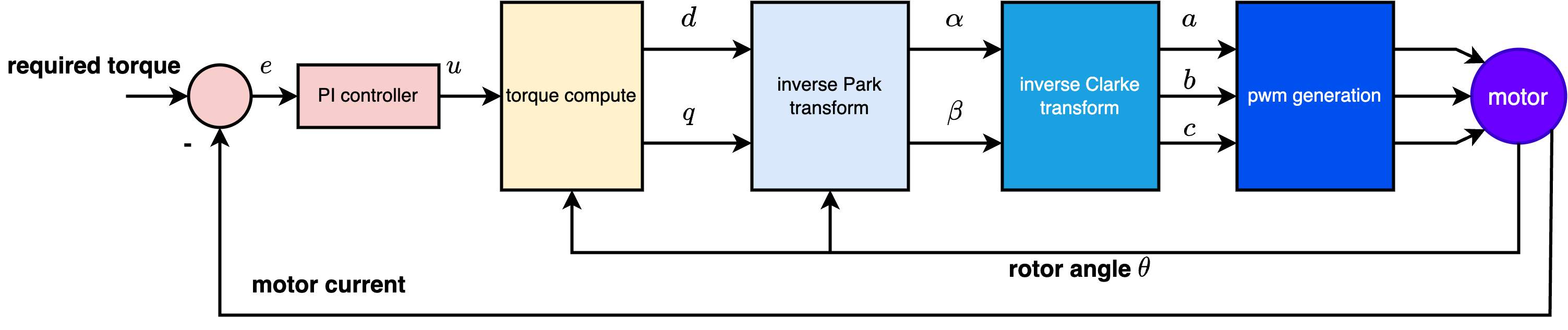

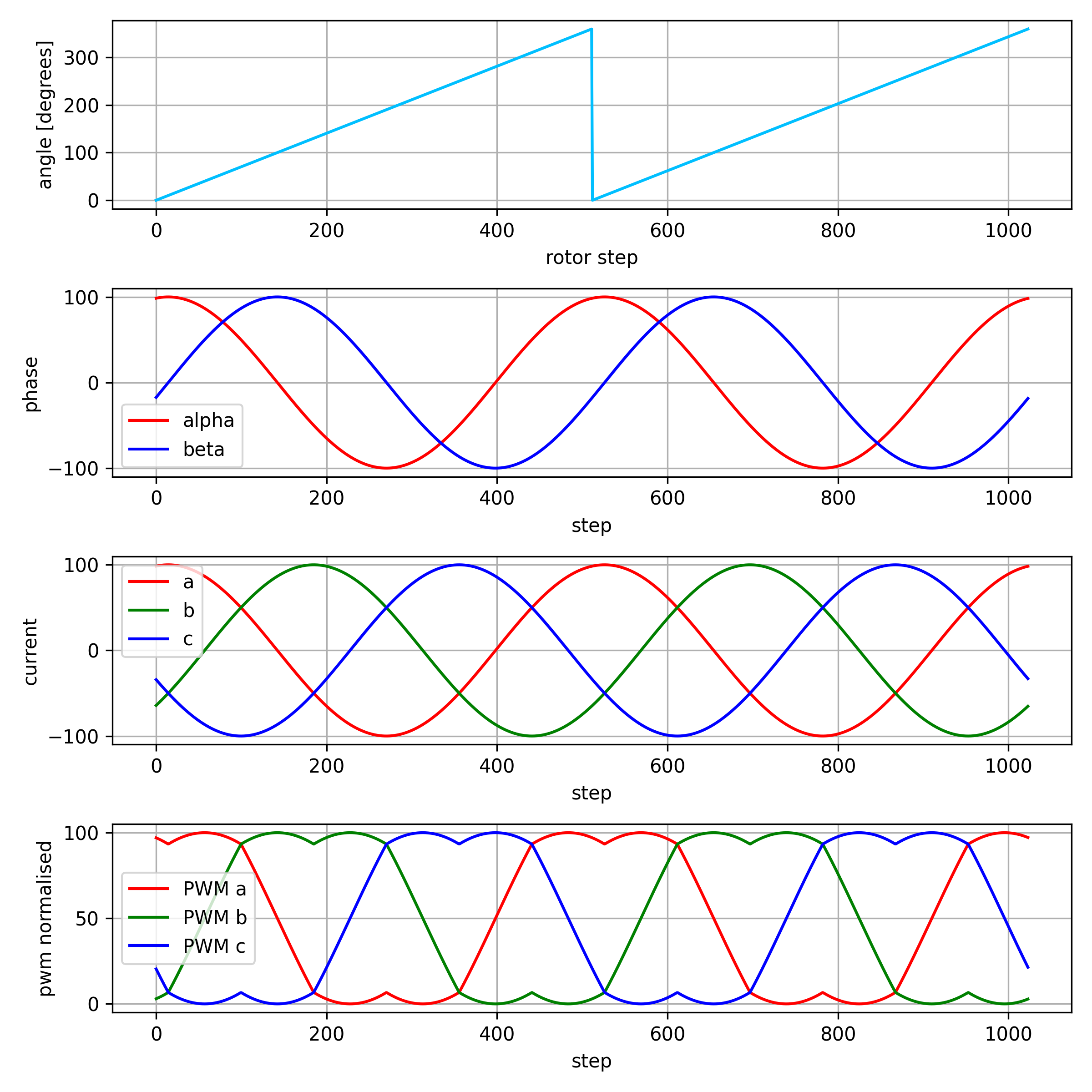

basic tranformations tests :

- clarke - park - pwm scaling

- see transform_test.py

- sine and cosine is precomputed, 1024 values arrays

- angle 2pi == 1024 (or 0) into tables

- theta ranges from <0, 1023>

- SINE_TABLE_MAX represents "one", 1023 in tables

- square root of 3 is also precomputed, as fraction of x/1024

- all divisions are by power of 2 - to avoid slow division

- this can easily run few kHz on cortex m0 (48MHz ARM)

#define SQRT3 ((int32_t)1773) // sqrt(3) = 1773/1024

#define SQRT3INV ((int32_t)591) // 1/sqrt(3) = 591/1024

void Motor::set_park(int32_t d, int32_t q, uint32_t theta)

{

//inverse Park transform

int32_t alpha = (d*cos_tab(theta) - q*sin_tab(theta))/SINE_TABLE_MAX;

int32_t beta = (d*sin_tab(theta) + q*cos_tab(theta))/SINE_TABLE_MAX;

this->set_clarke(alpha, beta);

}

void Motor::set_clarke(int32_t alpha, int32_t beta)

{

//inverse Clarke transform

int32_t a = alpha;

int32_t b = -(alpha/2) + (SQRT3*beta)/(2*1024);

int32_t c = -(alpha/2) - (SQRT3*beta)/(2*1024);

this->set_phases(a, b, c);

}

void Motor::set_phases(int32_t a, int32_t b, int32_t c)

{

//transform into space-vector modulation, to achieve full voltage range

int32_t min_val = min3(a, b, c);

int32_t max_val = max3(a, b, c);

int32_t com_val = (min_val + max_val)/2;

//normalise into 0..MOTOR_CONTROL_MAX

int32_t a_pwm = ((a - com_val)*SQRT3INV)/1024 + MOTOR_CONTROL_MAX/2;

int32_t b_pwm = ((b - com_val)*SQRT3INV)/1024 + MOTOR_CONTROL_MAX/2;

int32_t c_pwm = ((c - com_val)*SQRT3INV)/1024 + MOTOR_CONTROL_MAX/2;

a_pwm = clamp((a_pwm*PWM_PERIOD)/MOTOR_CONTROL_MAX, 0, PWM_PERIOD);

b_pwm = clamp((b_pwm*PWM_PERIOD)/MOTOR_CONTROL_MAX, 0, PWM_PERIOD);

c_pwm = clamp((c_pwm*PWM_PERIOD)/MOTOR_CONTROL_MAX, 0, PWM_PERIOD);

set_pwm(a_pwm, b_pwm, c_pwm);

}- controller is first discretised in constructor

- dt is sampling period in miliseconds

- kp, ki, kd are common controller constants, multiplied by 16384, to avoid floating point

k0 = kp + ((ki*dt)/1000) + ((kd*1000)/dt);

k1 = -kp - 2*((kd*1000)/dt);

k2 = ((kd*1000)/dt); - whole PID is just 3 multiplications and 4 additions

- to avoid integral windup, only clamping output is necessary

int32_t PID::step(int32_t error)

{

this->e2 = this->e1;

this->e1 = this->e0;

this->e0 = error;

int32_t du = (k0*e0 + k1*e1 + k2*e2)/16384;

u+= du;

//anti windup

if (u > antiwindup_max)

{

u = antiwindup_max;

}

if (u < antiwindup_min)

{

u = antiwindup_min;

}

return u;

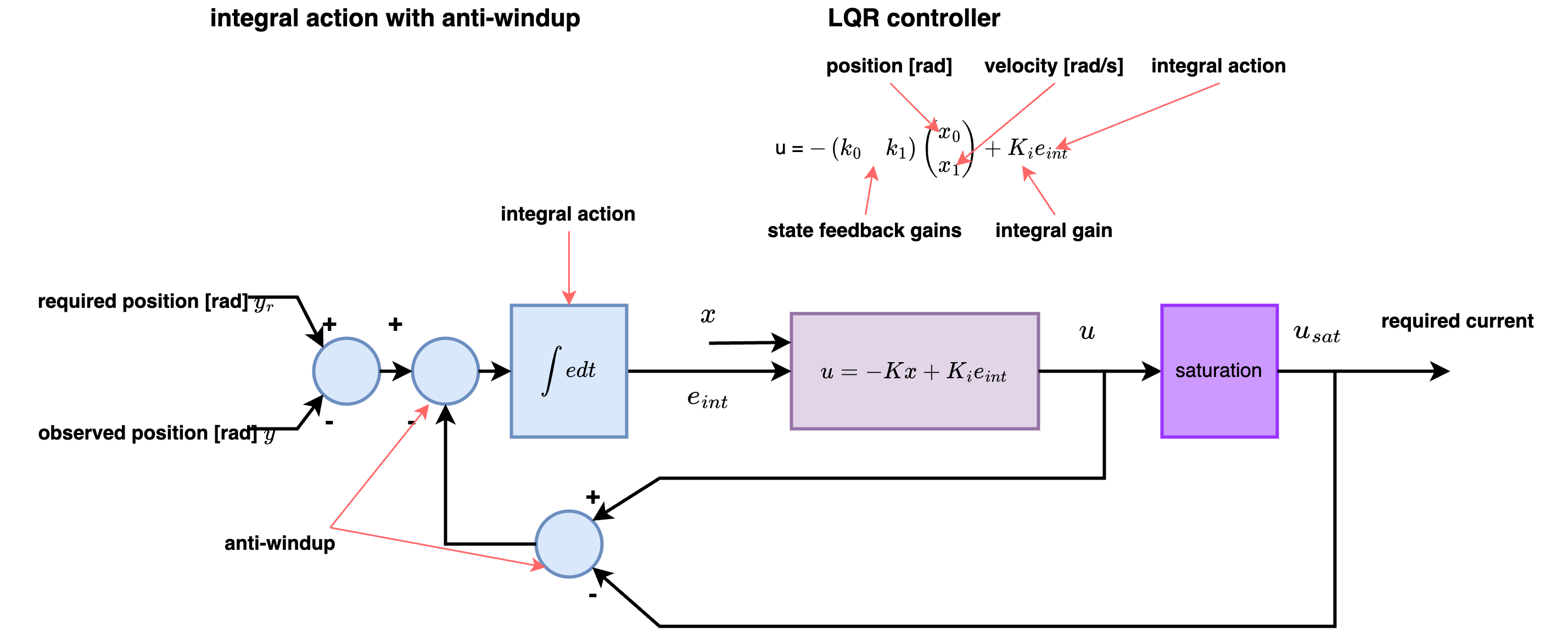

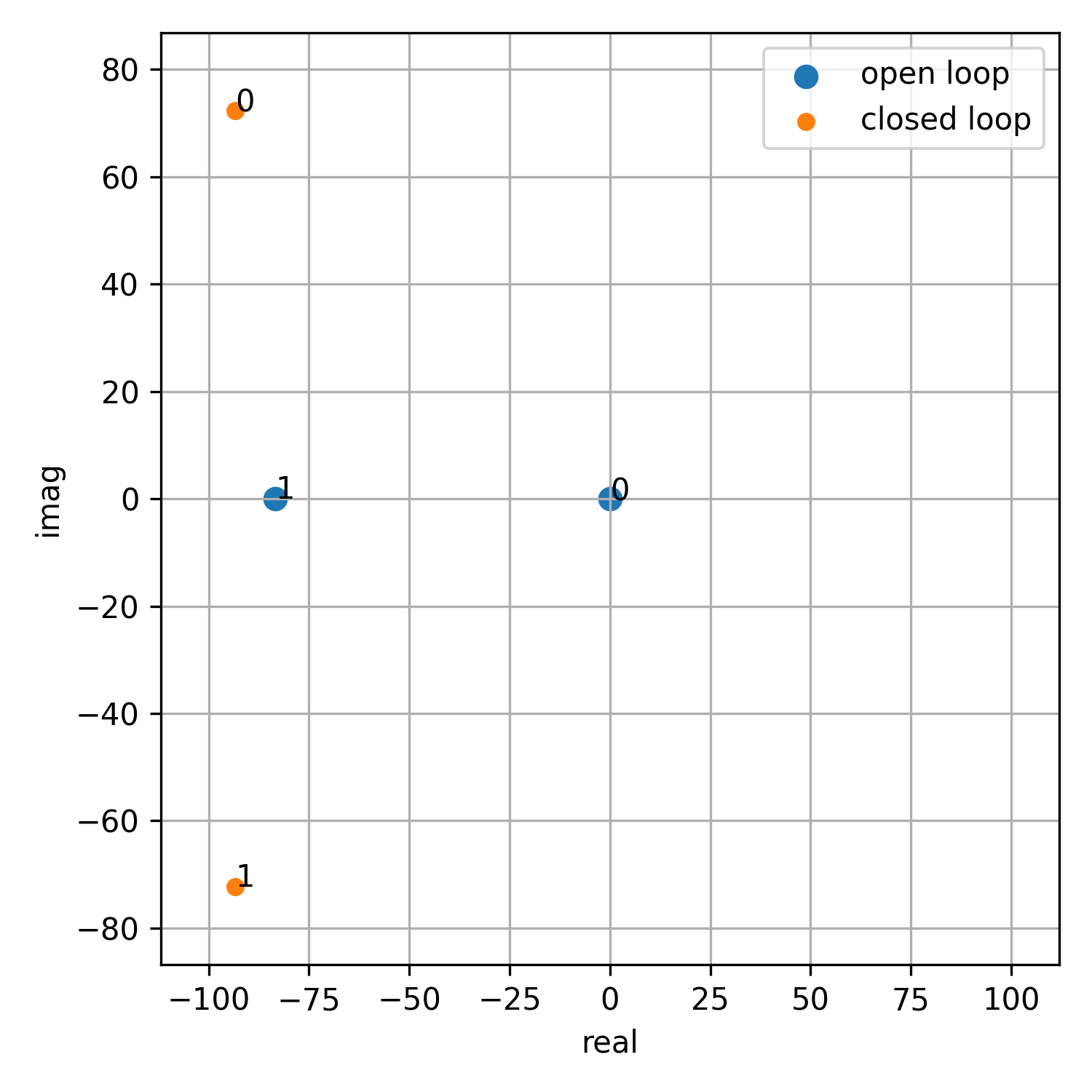

}see lqr_design.ipynb