Introduction

In this project, we are using the power of Multi Agent Systems to solve a complex problem. Each agent is a conveyor. The entire system consists of a network of conveyors with the goal of transferring the pallet from one point to another. Since there is no global knowledge of the system, and at any time a conveyor can be added, removed, or moved, Multi Agent Systems are the only way to go.

We are combining both Task 1 -- transfer control -- and Task 2 -- path finding algorithm: it is possible to send a request to a conveyor to transfer a pallet to another conveyor. The path finding algorithm finds the best path according to the number of conveyors involved. Then the transfer control moves the pallet via the best path. If any of the conveyors becomes "busy" or "down", the path finding algorithm is run again to find another path.

Theoretical background

The project is built on top of JADE technology: JADE is a Java framework developed by Telecom Italia used for the development of Multi Agent Systems. It also allows us to execute the agents into a simulation environment with graphical tools to manage and monitor them. The interaction between agents happens using the FIPA standard. All the requests and CFPs are in JSON format in which the type of the request and the arguments are specified.

Weakness and strengths of our solution

Our solution is capable of handling more than one pallet per time. If one conveyor is busy or down, the previous conveyor tries to send the pallet three times after waiting some time. In this way we can handle the situation of two pallets following different paths with one conveyor in common. If after three tries the following conveyor is still unavailable, the agent runs the path finding algorithm again. If a new path is found, the pallet is sent through the new path.

This solution is very handy but does not distinguish between the busy and the down state. By adding one more step of communication, it is possible to try three times only if the next conveyor is busy and look for new path from the beginning if the conveyor is down.

Future work

An infinite number of functionalities can be added to the agents, and some of the current can be improved or made more efficient. For example, instead of trying three times to send the pallet after waiting a definite amount of time, the conveyor could ask what the remaining time is and wait for it.

Also, the path finding algorithm can be based on the total transfer time and not the distance. With those improvements, the agent before a busy conveyor could either decide to wait for it to become idle again or follow another route if it is faster.

Inter-agents interactions

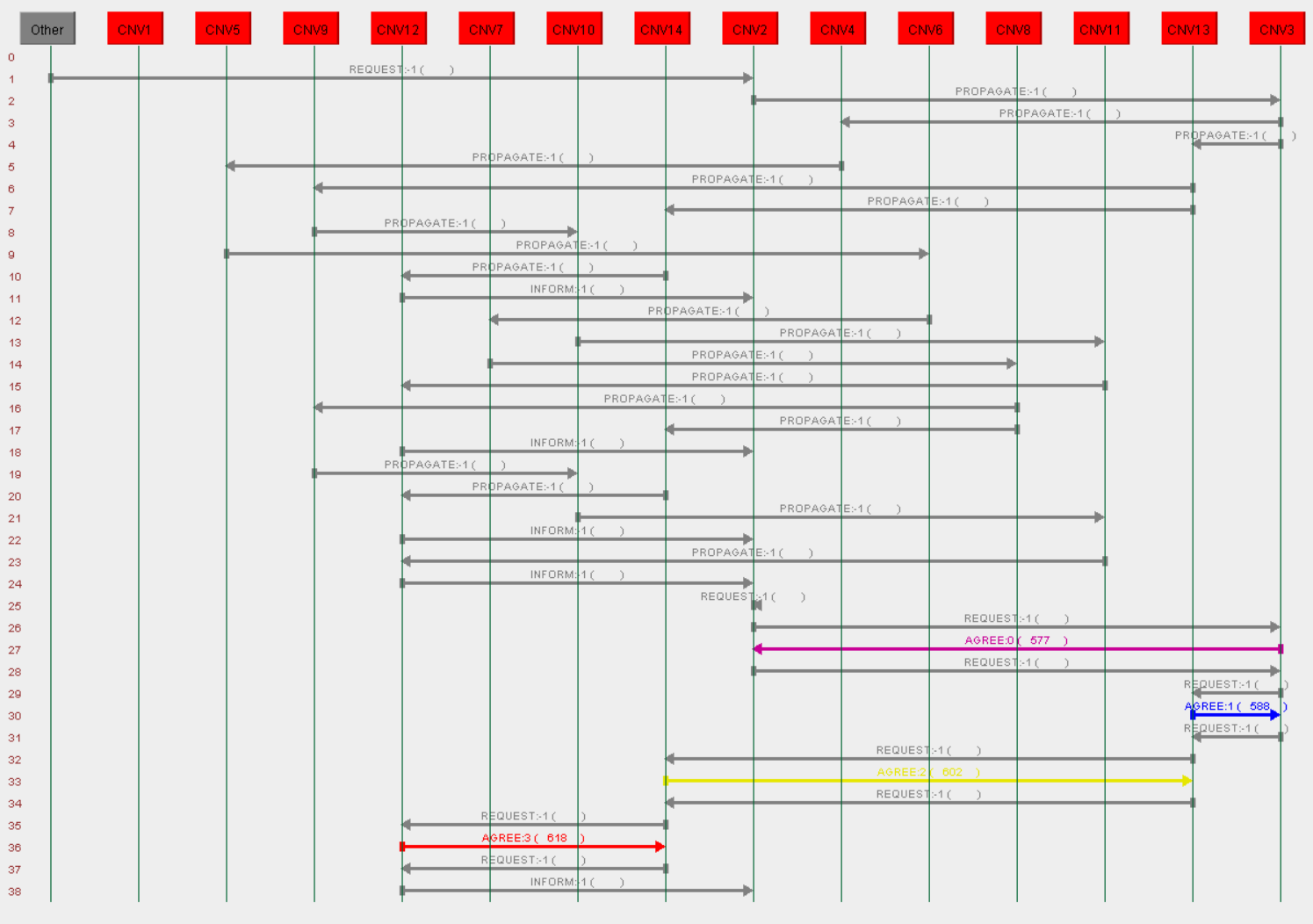

On line 1, the request for transfer from CNV2 to CNV12 is sent to

CNV21.

On line 2, CNV2 starts to propagate the pathfinding request, that is

spread across all the conveyors involved. The paths found are

transmitted back to CNV2 as INFORM type, routed_transfer messages (line

11, 18, 22, 24).

Agent CNV2 chooses the best path and sends a routed_transfer REQUEST to itself (line 25). Although this is not the most elegant solution, it is very convenient since it requires almost no modification to the already existing agent code and allows for an external user to step in in a simple way.

The real transfer begins.

For each step (there are four steps for this transfer), there is first a

load REQUEST (lines 26, 29, 32, and 35), that is followed by the AGREE

confirmation that the pallet has been correctly transferred. The last

REQUEST messages (lines 28, 31, 34, and 37) contain the routed_transfer

instruction.

On line 38, the destination conveyor (CNV12) sends an INFORM message to the source conveyor (CNV2), saying that the transfer is completed.

Conveyor agent logic

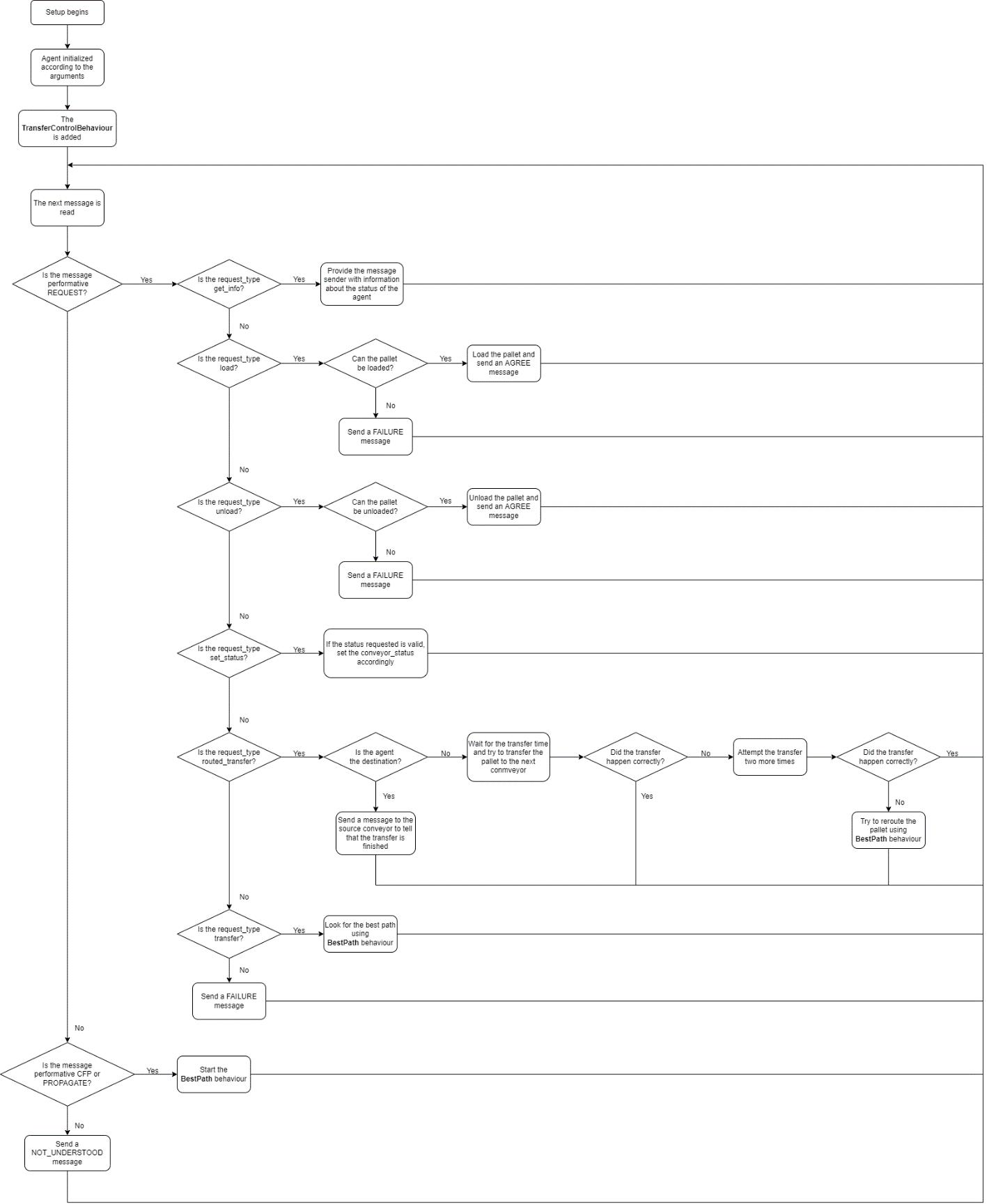

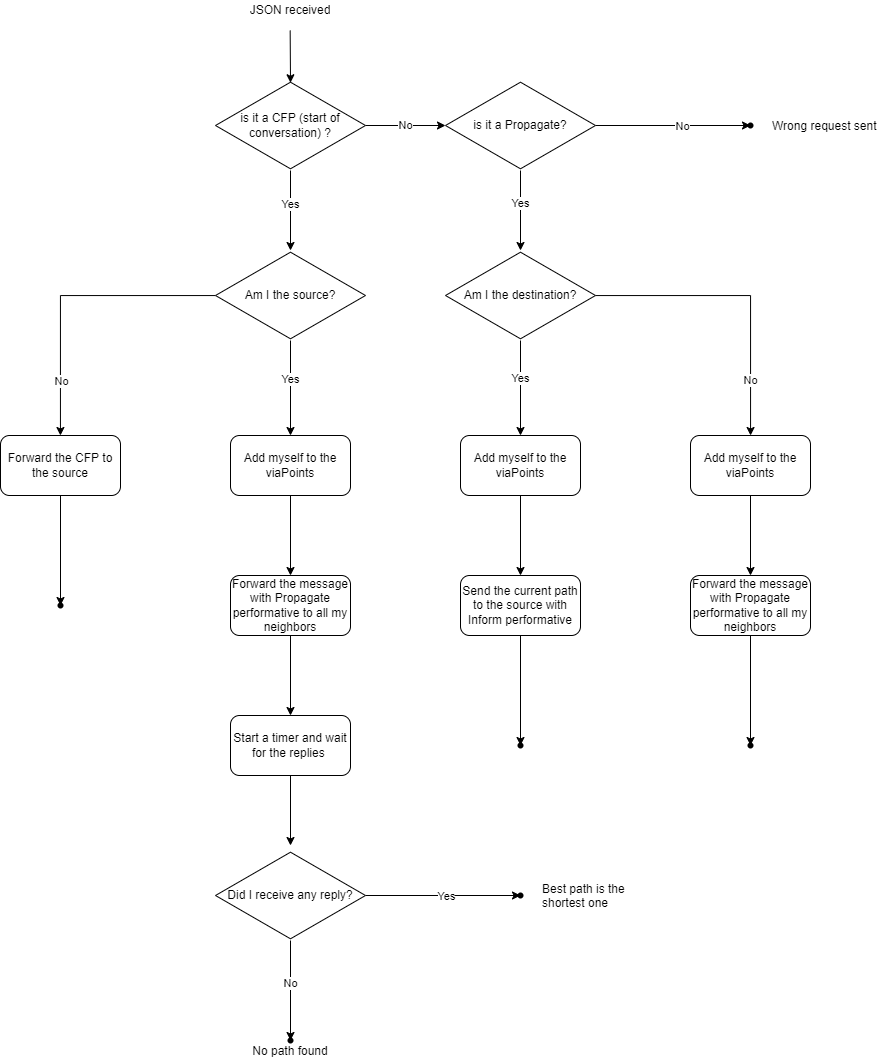

The logic of the ConveyorAgent can be represented using two flowcharts: one for the TransferControl Behaviour and one for the BestPath behavior.

Figure 1: TransferControlBehaviour flowchart

Figure 2: BestPath flowchart

Instructions to run and test our solution

The LayoutBuilderAgent will instantiate all the ConveyorAgents, which take as arguments the neighbours and the transfer time. It is possible to modify the default configuration of the system by changing the code in the LayoutBuilderAgent class. To instantiate a new conveyor, the lines to add are:

AgentController CNVx = containerController.createNewAgent("CNVx","agents.ConveyorAgent", new Object[][]{ {"CNVy","CNVz"}, {5}});

CNV1.start();

Where CNVx is the name of the conveyor to instantiate, CNVy and CNVz are its neighbours, and 5 is the transfer time (in this case). The transfer time is an integer value that stands for the number of seconds it takes the conveyor to transfer the pallet.

The LayoutBuilderAgent will also start a Sniffer agent already sniffing all the conveyors. If the names of the conveyors change, then the line telling the sniffer which agents to sniff must change accordingly.

The Conveyor Agents are programmed to handle several types of commands, sent as ACL messages.

| Performative | request_type | Attributes | Description |

|---|---|---|---|

| REQUEST | get_info | Sends back a message containing information about the status of the conveyor. | |

| load | Loads the conveyor with a pallet. | ||

| unload | Unloads the conveyor if it is loaded. | ||

| set_status | status: {Idle, Busy, Down} | Sets the status of the conveyor. | |

| routed_transfer | source | Requests the transfer of a pallet from the source conveyor to the destination conveyor, through the conveyors contained in the viaPoints array. If the reroute flag is set to true, then the conveyors will try to find alternative routes if the transfer fails. | |

| destination | |||

| viaPoints | |||

| reroute: {true, false} | |||

| transfer | source | Finds the best path from the source conveyor to the destination conveyor and begins the transfer. If one of the conveyors on the path is busy or down, the system will try to attempt the transfer three times before searching for an alternative path. | |

| destination | |||

| CFP | source | Tries to find the shortest path from the source conveyor to the destination conveyor. |

The content of the ACL message must be a JSON object containing the fields as specified in the table. An example command can be found below.

{

"request_type":"transfer",

"source":"CNV1",

"destination":"CNV12"

}

Footnotes

-

The content of the message is shown in the example on page 11 ↩