Export your Blender animation to servo position values. They can be used with an Arduino compatible micro controller to move PWM-driven servos according to your animation.

Animate your robot or animatronic project and take advantage of Blender's animation tools!

Also check out the Blender Servo Animation Arduino Library which is specifically designed to work with this add-on.

- Represent servos through armature bones

- Provide individual

Servo Settingsper bone - Export an animation as servo position values

- Send position values via a live mode connection in real-time

- Supporting Inverse Kinematics (IK)

Note: this Add-on is compatible with Blender version 2.90 or higher.

- Download the latest version of the Add-on as a ZIP archive.

- Open Blender and go to

File > Preferences > Add-ons. - Click the

Install...button, select the previously downloaded ZIP and clickInstall Add-on. - Enable the Add-on by checking the checkbox in the Add-ons list.

More information and screenshots can be found in the official Blender Manual.

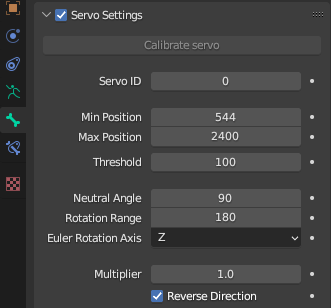

After enabling this Add-on, you should see a Servo Settings panel within the Bone Properties tab. This tab will be available once you select a bone while being in Edit or Pose mode.

The underlying principle is that each bone represents a servo motor in the real world. To treat a bone as a servo and activate the Servo Settings, enable the checkbox in the panel header.

| Property | Description |

|---|---|

| Servo ID | Unique number between 0 and 255 to identify this servo (used to send live commands) |

| Position Min | The minimum position value to identify this servo physically stops moving |

| Position Max | Same as Position Min, but for the maximum value |

| Threshold | The maximum value change between frames which is also used for frame jump handling in live mode |

| Neutral Angle | The assumed neutral angle of the servo in degrees (typically half the rotation range) which should be adjusted carefully, since the servo will first move to its 'natural' neutral angle when powered |

| Rotation Range | The manufactured rotation range of the servo in degrees (typically 180) |

| Euler Rotation Axis | The Euler rotation axis (X, Y or Z) of the bone rotation representing the servo movement |

| Multiplier | Multiplier to increase or decrease the rotation to adjust the intensity within a specific build |

| Reverse Direction | Whether the applied rotation should be reversed when converting to position value which might be necessary to reflect the servo's positioning within a specific build |

The default position min and max values are based on servo pulse lengths as they are required when using a library to control a servo driver module, like the PCA9685.

It is also possible to use a different kind of value range. For example, to use the default Arduino Servo library, you can use a degrees value range by setting min to 0 and max to 180.

Note: the correct settings vary between different servo brands and models. Be careful not to damage the servo when finding the min and max position values.

You can take advantage of Blender's functionality and use bone constraints to already limit the bone rotation according to your build. The more precise your 3D model, the easier it will be to apply constraints and get an accurate preview of the real-world setup.

When animating your armature you can benefit from all the exciting animation features Blender has to offer. Apart from animating every bone/servo separately, you can also use IK (Inverse Kinematics) to let the Add-On calculate the positions of multiple servos automatically.

When thinking of animatronic or robotic projects, you could animate a head or arm without having to worry about the individual bones/servos that make up the neck mechanism or arm segments. To further illustrate this, you can also find an example of a neck mechanism to learn about the armature and constraints setup.

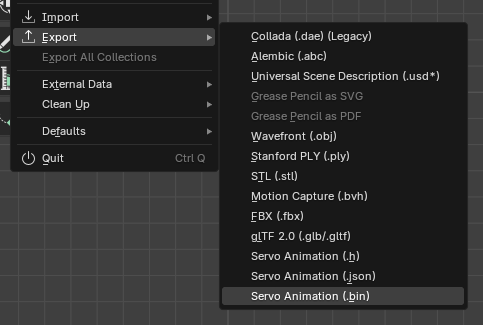

Once all servo settings are provided and your animation is ready, you can calculate and export the servo position values.

Make sure to select the armature containing the bones/servos you want to export and choose the desired format in the File > Export menu:

Alternatively, you can also trigger the export via the timeline menu which is shown in the live mode section below.

There are two different formats to choose from:

Animation Servo Positions (.h): An Arduino/C/C++ style header file which can be easily included in an Arduino project.Animation Servo Positions (.json): A simple (non-formatted) JSON file which can be used in a more generic way.

For projects which involve an Arduino compatible microcontroller, the easiest way to work with the exported data is by using the dedicated Blender Servo Animation Arduino Library. This library allows you to map the exported positions to a servo representation and add custom logic to actually send servo control signals. Check out the library's repository for more details and some read-to-use examples.

Apart from using the library, it is also possible to write use the exported data in any other kind of program. Especially the JSON format simply represents a list of position values which can be easily parsed via code.

To make the animation process even more intuitive, you can enable the Live mode to send position commands via one of the following connection types:

- Serial (UART/USB)

- Web socket (TCP)

This will allow you to control your servos in real-time from within Blender.

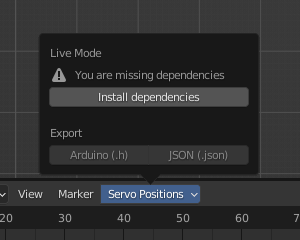

After enabling the add-on, you can find the Servo Positions popover menu in the header of the timeline. Before using the live mode feature of this add-on, you might have to install some Python dependencies first by pressing the Install dependencies button. This will automatically install the required pip packages and requires an active internet connection. This process can might take a few seconds depending on the speed of your internet connection.

Afterwards you can prepare and control the connection to be used for the Live mode via this menu. For additional convenience, you will also find buttons to export the servo positions here.

To use the Live Mode, you will need to prepare a receiver which will interpret the received commands and use them to control the servo motors accordingly.

In most cases, the receiver can be considered an Arduino compatible micro controller. As a first step, a connection method should be selected via the Method dropdown menu.

Note: starting the

Live Modewill immediately send the position values for all servos based on the current frame. Make sure that this will not break anything, as the servos will try to move to their new position as fast as possible.

Once the micro controller is connected via USB to your PC, the add-on will try to find and list the respective Serial Port. If there are multiple ports and you are unsure which one belongs to your controller, simply compare the list of ports after removing and re-connecting the device.

The Baud Rate specifies at which rate or speed the data will be transferred. It might need to be adjusted according to the limitations and configurations of your receiver. Keep in mind that a high frame rate combined with a multitude of servos requires a faster data transmission to achieve a smooth movement. As a reference, it was possible to smoothly control 16 servos at 60 fps with a baud rate of 115200.

Once the Serial Port and Baud Rate have been set, you can click the Connect button to establish the serial connection and start the Live Mode.

It is also possible to send the position values via a TCP-based web socket connection. For example, one could use a WiFi-capable micro controller like the ESP32 and set up a server to receive commands from Blender. The server should be in the same network as the machine which is running Blender.

After starting such a server, we can enter the respective IP address and port into the Host and Port input fields.

Clicking the Connect button will then establish a tcp connection and start the Live Mode.

Once the connection is established, you can use the timeline to control your servos in a synchronized way. This opens up the possibility to jump to a different frame or position within your animation. To prevent damage due to the servos moving too quickly, you can use Position Jump Handling. This option is enabled by default.

When clicking somewhere in the timeline and therefore jumping to a different frame, the add-on will first calculate all position value differences. If one of those differences exceeds the Threshold value of the respective servos, they will be slowly moved to their new target position. This is done by sending multiple position values in small increments. During this process, the user interface will show a progress indicator.

The speed of this process is also relative to the configured Threshold values. A slower and safer movement can be achieved by setting the threshold values as low as possible with the actual animation still able to run properly.

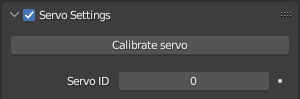

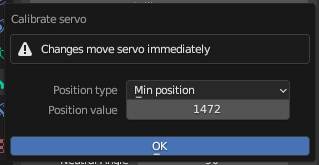

While having an active live mode connection, it is possible to use a servo calibration feature. This will allow you to find the minimum and maximum position value of a servo similar to what you would normally do with a servo tester.

The calibration process can be started by clicking the Calibrate servo button within the servo settings panel:

Note: the button will only be clickable when there is an active live mode connection.

Clicking this button will bring up a dialog containing a drop down menu to switch between the minimum and maximum position. You can then carefully adjust the position value until the servo stops moving. After doing so for both directions or position types, you can click on OK to apply these values as the new min and max position values.

Note: Be careful when changing the position value and toggling the position type as the servo will move at full speed and position jump handling is not being considered.

To cancel this process you can either press ESC or click outside the dialog box. While position jump handling is not considered during the calibration process it is again considered when cancelling or applying the calibration.

The position values are sent based on a specific binary protocol. The receiver has to know about it and be able to interpret the received data in order to successfully trigger the correct servo movement.

The protocol defines in which order and pattern individual bytes are transferred. The following table shows the protocol structure based on an example where the servo with the ID 0 should receive the position value 375:

| Start | Servo ID | High Pos | Low Pos | End | |

|---|---|---|---|---|---|

| ASCII | < | 0 | 1 | 119 | > |

| Decimal | 60 | 0 | 1 | 119 | 62 |

| Hexadecimal | 0x3C | 0x00 | 0x01 | 0x77 | 0x3E |

The position value is split into 2 bytes (high and low), while the first byte is the most significant one.

Instead of writing your own logic to read and interpret the live mode commands, you can also use the Blender Servo Animation Arduino Library which has a built-in support for the live mode. Check out the library's repository for more details and some ready-to-use examples.