This project includes high voltage applications and has health, death and destruction of equipment risks. Please check this article if you are not really familiar with high voltage: Work Safely With High Voltage.

And please do not use the USB port on the microcontroller at all when you are powering it from somewhere else, it might damage your computer.

- PID - temperature control

- Auto tune for PID - PID values can be tuned automatically

- Pressure control - controls pump with PWM dimmer

- Indicator light - shows when the temp is ideal to start brewing

- Preinfusion - ability to run pump in a different value for a period before brewing

- Brew timers - precise control on brewing and preinfusion time, the pump automatically shut downs once the timer stops

- Configurable - all values are configurable without needing another device

- Persistance - all changes (including auto tuning) persist between power cycles

- Sleep mode - if the machine is forgotten on, it shuts down automatically

- Steam PID - separate temperature control options for steaming

- Intuitive UI - the menu is displayed with big fonts and navigated with three buttons:

- Minus - decreases/disables selected value

- Option - moves cursor to next item

- Plus - increases/enables selected value

- Realtime graph - temperature graph and current status displayed while brewing

- Quality of live improvements - ex: when steam is enabled the cursor moved to the steam temp automatically, current temperature displayed on temperature related elements in the menu

- Safety - all 240v components lives inside the machine where they are out of touch. There is only 5v max coming outside of the machine.

The current implementation is separated as user input, state, user output and coffee machine. Input is read from buttons for now, a web UI/app can be implemented for this part. This input data is given to state to modify state data. State also handles with max/min limits, persistance and its planned to handle profiles as well. User output is currently only the display a web UI can be added in this step as well. Each section of the UI is represented with a function that takes input what to print. And the coffee machine part is implemented in main file to keep everything together and readable.

- Better PID control, right now its not as good as I want it to be so it requires a bit tuning

- Profiles - different settings stored on device for different beans/water that can be changed easily

- wifi/app/cloud support

- unit tests and integration tests

- better architecture for different parts in main.cpp (calibrate,input,temp control,display)

- 3D printed boxes and mounting for two different parts. Inner parts consisting the relay, power source and dimmer. And outer parts consisting the controller, screen, buttons.

- Circuit design for outside unit to make it more compact

- Fix boot failure on boot with brew button enabled. (This might be impossible since I run out of pins to use and this pun causes boot fail when pulled to low)

- Find a better way to handle solenoid valve

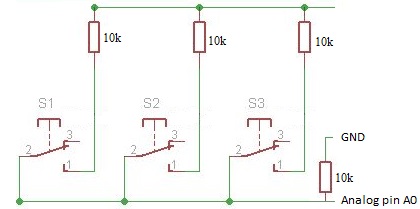

There are 5 input buttons: - Minus - decreases/disables selected value - Option - moves cursor to next item - Plus - increases/enables selected value - Steam - the steaming button on the machine itself - Brew - the brewing and pump button on the machine itself Three of these buttons (minus,option,plus) connected with analog input and voltage divider circuits. I use six 10k resistors to build the circiut but other values are also possible. Only thing required is to have different values for each button connection. Then MINUSVAL, OPTIONSVAL and PLUSVAL can be modified for the new resistor values. You can calculate it using the formulas in the input.buttons.cpp but best way to do it is by experimenting. You can build a simple code that reads analog input and prints and click on the buttons one by one to set their values. This is required since the components required by this project uses up all the pins on nodemcu v3. If you are using a board with more pins you can connect them directly with digital input and modify input.buttons.cpp accordingly.

This image resourced from codebender_cc at instructables, you can also find more information about this button circuit design there.

If you want to build an enclosure for buttons and screen as well, please include back support for the buttons otherwise with the force applied the buttons can shift. You can see my crappy back support (two hot glued plastic sticks that reaches to the end of the box for support) in the picture:

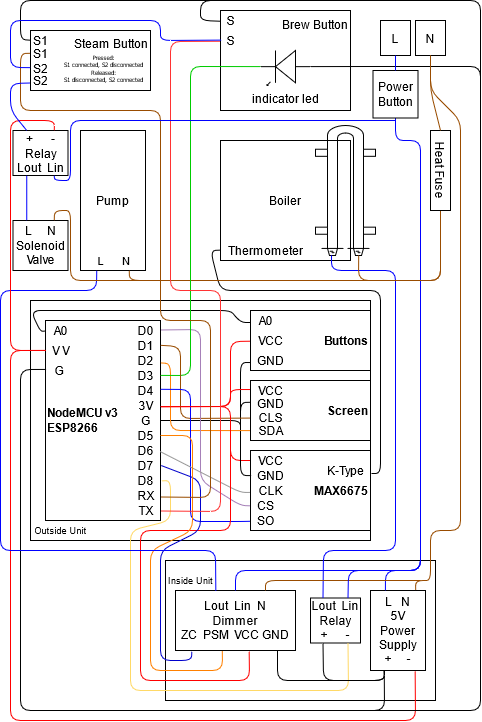

Heater is connected with a relay, I used SSR-40DA on D8 (pin 15). For some reason the relay I got was marked in reverse (+ instead of - and minus instead +), or I did something wrong (I used + as ground hope thats correct). I did not reflect that to circuit diagrams but if your relay doesn't work correctly check which terminal is ground in a separate setup. Solenoid valve is also connected with a relay, I used SSR-40DA with a button logic, basically i copied to same logic classic design has in high voltage to the low voltage. Pump is connected with robotdyn dimmer module on D5 (pin 14) for PWM and on D7 (pin 13) for zero-cross detection (z-c).

I used a m4 threaded thermocouple with MAX6675. Its connected as follows: SO: D4 (pin 2) CS: D0 (pin 16) CLK: D6 (pin 12) You can modify temp.sensor.h if you want to change the setup. You can find more information on how to wire temp sensor and screen here

I used a SSD1306 on D1 (pin 5) for CLS and D2 (pin 4) for SDA. You can find more information on how to wire temp sensor and screen here

I have used this power supply since its cheap and compact. If you are not good with soldering I dont recommend this one since it requires to solder high voltage and low voltage cables.

I added to the source code the pin names based on NodeMCU v3 (esp8266) and I also added cable color for the external connections but of course that changes depending how you implement the circuit so the colors can be ignored.

Technically you can change which pins to use and make it so closer pins serve the same component. But its definitely not recommended and changing pin layout randomly can cause boot fails or component fails. I had to do a lot of trial and error to make sure everything works. If you can use a pin extender it might gave you more freedom.

This is due to ESP8266's design, not every pin has the same capability and pulling some pins to low or high can cause boot fails, and not every pin can be used for interrupts and interrupts used by the dimmer module to function. This page provides more information for which pins to use: thehookup's nodemcu pin document

Since I switched the button logic from high voltage to 3.33v logic, and the button logic was also controlling the pump and the solenoid valve I needed to control both of these components now. Pump was already required since I wanted to use a dimmer to control pressure. But solenoid valve was a bit of a challenge since I already run out of pins on nodemcu v3. I can implement brew button in high voltage and use its output as Lin to dimmmer module so it can also control solenoid valve as it used to. But this solution doesn't allow me to detect when the brewing starts, I need to trigger the timers when brewing starts. Let me know if there is a solution I can not see here.

Solenoid Valve supposed to be enabled with 220v only when the pump is running or the steam mode is not enabled for my coffee machine (gaggia classic). The steam button is connected to two different independent switches that runs in reverse (or not logic). When you press the steam button, you connect the terminals for switch 1 and disconnect the terminals for switch 2. Switch 1 used to be connected to steam temperature breaker, now its connected to nodemcu. And switch 2 is connected to solenoid valve on one end, and the brew button on the other end. So when you run the pump without steam mode, solenoid valve enables. And if you shut down the pipe solenoid valve disables. When you run the pump in steam mode (steam button pressed and switch 2 is disconnected), the solenoid valve stays disabled.

I have solved by implementing the old connections it had in 3.33v logic and then use a second relay to convert 3.33 signal to high voltage. You can see it in circuit diagram.

I have used this hobby box and a dremel to build a box to hold all the electronic. If you are going to use the same method order multiple boxes to perfect your hand on using the dremel. You can prefer to only have the screen and buttons outside and keep everything mounted inside the machine as well, but this design allows modularity and development separated from the machine. I designed a mock coffee machines with three leds and two buttons to be able to test it. One led turns on if the heater is on, another one turns on if the pump is on and brightness changes thanks to PWM representing pump power. And the last led acts as the indicator led. The two buttons acts like the steam and brew button. The box I used was a bit small as well so I had to implement 90 degree angled short connectors to be able to keep everything modular. I cut off the plastic clip holding the plastic housing around the regular connectors, pull out the plastic housing and bend the pin. Then I cut the plastic housing to a quarter. And hot glued that to connector.

I really want to design a 3D printed box for this project, but I wanted to be able to build a prototype first to see what I need, and I was looking for excuses to use a dremel.

I also kept all high voltage components inside the machine (Relay, dimmer, power supply). I hot glued these components to the relay and mounted that with zip ties.