This repository compares two approaches to injecting fluid at a fixed flow rate and temperature in MOOSE's PorousFlow Thermo-hydro simulations. The first approach fixes the temperature at the inlet using a DirichletBC, while the second approach injects an amount of enthalpy based on the inlet fluid temperature using a PorousFlowSink BC.

The domain is initially at zero degrees and has a BCs that encourage a flow of 40000 kg/s, or 40 m3/s, across it (which is accomplished in input_initialization.i). After the initialization period, the inlet temperature is raised in one of two ways: (a) the temperature at the boundary is raised to 1 degree (input_PresetBC.i) or (b) the relevant enthalpy injection rate is specified (i.e. the enthalpy from 40000 kg/s at 1 degree, in input_PFSink.i). The outflow boundary produces fluid at 40000 kg/s and allows temperature to leave with the fluid. This is achieved by having very similar PorousFlowSink cards at the outlet for temperature and pressure. The only difference are the variable names (temp instead of pp) and that use_enthalpy is included for the temperature condition.

[./production]

type = PorousFlowSink

variable = pp

boundary = right

flux_function = 200 ## extraction of fluid at 200 kg/m2/s

fluid_phase = 0

use_mobility = false

save_in = fluxes_out

[../]

#Note that production_heat is identical to production at outflow boundary

#except that variable = temp and use_enthalpy = true

[./production_heat]

type = PorousFlowSink

variable = temp

boundary = right

flux_function = 200

fluid_phase = 0

use_mobility = false

use_enthalpy = true

save_in = heat_fluxes_out

[../]

We use the SimpleFluidProperties equation of state: Viscosity = 1 Pa-s, heat capacity = 4200 J/kg/K, reference density = 1000 kg/m3, bulk modulus of the fluid = 2e9 Pa. The rock material properties are: permeability = 10^-7 m2, porosity = 0.1, rock density = 2500 kg/m3, specific heat capacity = 800, dry thermal conductivity = 2.1, wet thermal conductivity = 1.8. The domain is 200 x 1 x 200 m and the area of the injection and extraction BCs are 200 m2.

The enthalpy injection rate is the product of the flow rate, the fluid heat capacity, and the temperature change = 40,000 kg/s * 4200 J/kg/K * 1 K = 1.68e8 J/s. Dividing by the area gives the flux_function = 840000 J/m2/s for the PorousFlowSink BC in input_PFSink.i.

[./injection_heat]

type = PorousFlowSink

variable = temp

boundary = left

flux_function = -840000. #This is the amount of enthalpy calculated a priori

fluid_phase = 0

use_mobility = false

use_enthalpy = false #NOTE this is false since a priori calculation was already done for flux_function

save_in = heat_fluxes_in

[../]

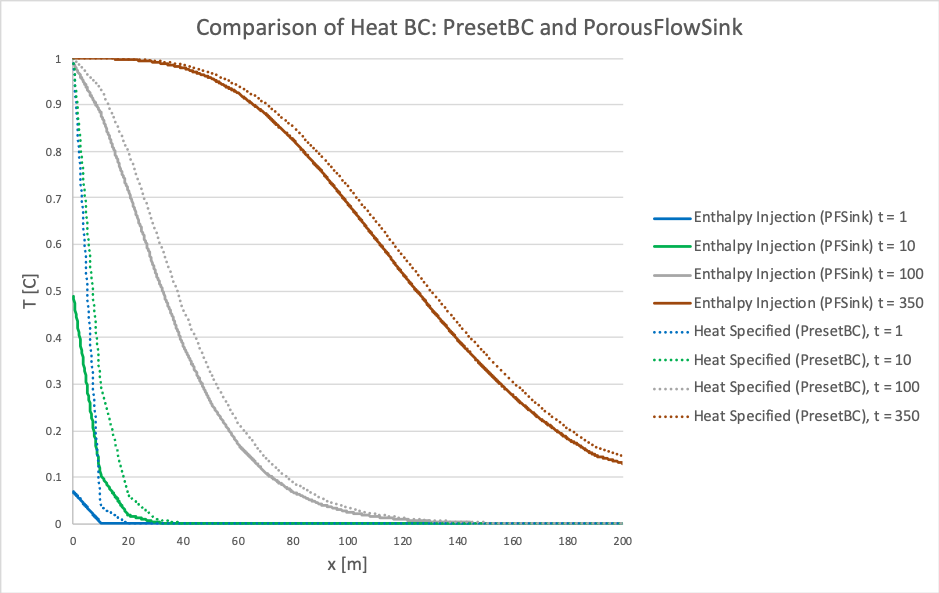

The figure below shows temperature versus distance along the flow path, x. Results are shown at t = 1, 10, 100, and 350 seconds. The solid lines are the results when an enthalpy injection rate is specified (with PorousFlowSink), and the dotted lines are results when the temperature is directly specified (with PresetBC). At early times, the enthalpy injection approach has to heat up the element at the injection. By t = 100, the temperature at the inlet is approximately 1 degree C. On the other hand, when the temperature at the inlet is fixed to 1 degree, the temperature gradient is very large at the inlet, essentially providing an unrealistically large amount of energy at early times. By the time the simulation has reached later times (t >=350 s), the differences between the two approaches are minor. It is likely that the enthalpy specification is more accurate than the fixed temperature BC, but the differences may be inconsequential depending on specifics of the problem (mesh size, time scale, length scale, material properties, etc.).