For simplified Chinese version: 简体中文版

For UFACTORY Lite 6 users, make sure you have followed the instructions before chapter 4.7 on this page, then switch to ReadMe for Lite6.

For kinetic users, please use the kinetic branch.

Topic "xarm_cgpio_states" has been renamed to "controller_gpio_states".

After using xArm C++ SDK as sub-module, the use of /xarm/set_tool_modbus service has been modified, compared with old version, the redundant '0x09' byte in response data has been removed!

Due to robot communication data format change, early users (xArm shipped before June 2019) are encouraged to upgrade their controller firmware immediately to drive the robot normally in future updates as well as to use newly developed functions. Please contact our staff to get instructions of the upgrade process. The old version robot driver can still be available in 'legacy' branch, however, it will not be updated any more.

You MUST follow chapter 3 to install additional packages needed before any usage of xarm_ros packages. Otherwise, unexpected errors may occur.

If developing with Moveit, it is highly recommended to use DIRECT network cable connection between controller box and your PC, and no intermediate switches or routers, or the communication latency may have a bad impact on trajectory execution.

When updating this package, please remember to check the submodule update as well!

- 1. Introduction

- 2. Update History

- 3. Preparations (MUST DO)

- 4. Get Started

- 5. Package Description & Usage Guidance

- 5.1 xarm_description

- 5.2 xarm_gazebo

- 5.3 xarm_controller

- 5.4 xarm_bringup

- 5.5 xarm7_moveit_config

- 5.6 xarm_planner

- 5.7 xarm_api/xarm_msgs (Online Planning Modes Added)

- 5.7.1 Starting xArm by ROS service (priority for the following operations)

- 5.7.2 Joint space or Cartesian space command example

- 5.7.3 Tool/Controller I/O Operations

- 5.7.4 Getting status feedback

- 5.7.5 Setting Tool Center Point Offset

- 5.7.6 Clearing Errors

- 5.7.7 Gripper Control

- 5.7.8 Vacuum Gripper Control

- 5.7.9 Tool Modbus communication

- 5.7.10 'report_type' argument

- 5.8 xarm_moveit_servo

- 6. Mode Change(Updated)

- 7. xArm Vision

- 8. Other Examples

This repository contains the 3D models of xArm series and demo packages for ROS development and simulations.Developing and testing environment: Ubuntu 16.04/18.04/20.04 + ROS Kinetic/Melodic/Noetic.

Instructions below is based on xArm7, other model user can replace 'xarm7' with 'xarm6' or 'xarm5' where applicable.

This package is still under development and improvement, tests, bug fixes and new functions are to be updated regularly in the future.

- Add xArm 7 description files, meshes and sample controller demos for ROS simulation and visualization.

- Add Moveit! planner support to control Gazebo virtual model and real xArm, but the two can not launch together.

- Add Direct control of real xArm through Moveit GUI, please use it with special care.

- Add xArm hardware interface to use ROS position_controllers/JointTrajectoryController on real robot.

- Add xArm 6 and xArm 5 simulation/real robot control support.

- Add simulation model of xArm Gripper.

- Add demo to control dual xArm6 through Moveit.

- Add xArm Gripper action control.

- Add xArm-with-gripper Moveit development packages.

- Add vacuum gripper model and xArm-with-vacuum-gripper Moveit development packages (under /examples dir).

- Thanks to Microsoft IoT, xarm_ros can now be compiled and run on Windows platform.

- Add velocity control mode for joint and Cartesian space. (xArm controller firmware version >= 1.6.8 required)

- Add support for custom tool model for Moveit

- Add timed-out version of velocity control mode, for better safety consideration. (xArm controller firmware version >= 1.8.0 required)

- Add xArm Vision and RealSense D435i related demo. Migrate previous "xarm_device" into xarm_vision/camera_demo.

- xarm_controler (xarm_hw) no longer uses the SDK through service and topic, but directly calls the SDK interface.

- Add text interpretation for Controller Error code, returned from "get_err" service.

- Support UFACTORY Lite 6 model.

- [Beta] Added two more torque-related topics (temporarily do not support third-party torque sensors): /xarm/uf_ftsensor_raw_states (raw data) and /xarm/uf_ftsensor_ext_states (filtered and compensated data)

- (2022-09-07) Add service(set_tgpio_modbus_timeout/getset_tgpio_modbus_data), choose whether to transparently transmit Modbus data according to different parameters

- (2022-09-07) Update submodule xarm-sdk to version 1.11.0

- (2022-11-16) Add torque related services: /xarm/ft_sensor_enable, /xarm/ft_sensor_app_set, /xarm/ft_sensor_set_zero, /xarm/ft_sensor_cali_load, /xarm/get_ft_sensor_error

- (2023-02-10) Added xarm_moveit_servo to support xbox controller/SpaceMouse/keyboard control

- (2022-02-18) Automatically saving in servie(/xarm/ft_sensor_cali_load) and add torque related service(/xarm/ft_sensor_iden_load)

- (2023-02-27) Added service to control Lite6 Gripper(/ufactory/open_lite6_gripper, /ufactory/close_lite6_gripper, /ufactory/stop_lite6_gripper)(Note: Once stop, close will be invalid, you must open first to enable control)

- (2023-03-29) Added the launch parameter model1300 (default is false), and replaced the model of the end of the xarm robot arm with the 1300 series

gazebo_ros_pkgs: http://gazebosim.org/tutorials?tut=ros_installing (if use Gazebo)

ros_control: http://wiki.ros.org/ros_control (remember to select your correct ROS distribution)

moveit_core: https://moveit.ros.org/install/

ROS Wiki: http://wiki.ros.org/

Gazebo Tutorial: http://gazebosim.org/tutorials

Gazebo ROS Control: http://gazebosim.org/tutorials/?tut=ros_control

Moveit tutorial: http://docs.ros.org/kinetic/api/moveit_tutorials/html/

In Gazebo simulator, navigate through the model database for 'table' item, drag and place the 3D model inside the virtual environment. It will then be downloaded locally, as 'table' is needed for running the demo.

If simulating xArm Gripper in Gazebo is needed, mimic_joint_plugin by courtesy of Konstantinos Chatzilygeroudis (@costashatz) needs to be installed in order to make the mimic joints behave normally in Gazebo. Usage of this plugin is inspired by this tutorial from @mintar.

12/22/2020: Refer to issue #53, Please Note this plugin has recently been deprecated, if you plan to use new version, please change "libroboticsgroup_gazebo_mimic_joint_plugin.so" to "libroboticsgroup_upatras_gazebo_mimic_joint_plugin.so" in file: xarm_ros/xarm_gripper/urdf/xarm_gripper.gazebo.xacro

If you already have a workspace, skip and move on to next part. Follow the instructions in this page. Please note that this readme instruction assumes the user continues to use '~/catkin_ws' as directory of the workspace.

$ cd ~/catkin_ws/src

$ git clone https://github.com/xArm-Developer/xarm_ros.git --recursive$ cd ~/catkin_ws/src/xarm_ros

$ git pull

$ git submodule sync

$ git submodule update --init --remote$ rosdep update

$ rosdep check --from-paths . --ignore-src --rosdistro kineticPlease change 'kinetic' to the ROS distribution you use. If there are any missing dependencies listed. Run the following command to install:

$ rosdep install --from-paths . --ignore-src --rosdistro kinetic -yAnd chane 'kinetic' to the ROS distribution you use.

$ cd ~/catkin_ws

$ catkin_make$ echo "source ~/catkin_ws/devel/setup.bash" >> ~/.bashrcSkip above operation if you already have that inside your ~/.bashrc. Then do:

$ source ~/.bashrc$ roslaunch xarm_description xarm7_rviz_display.launch$ roslaunch xarm_gazebo xarm7_beside_table.launch [run_demo:=true] [add_gripper:=true] [add_vacuum_gripper:=true] Add the "run_demo" option if you wish to see a pre-programed loop motion in action. The command trajectory is written in xarm_controller\src\sample_motion.cpp. And the trajectory in this demo is controlled by pure position interface.

Add the "add_gripper" option if you want to see the xArm Gripper attached at the tool end.

Add the "add_vacuum_gripper" option if you want to see the xArm Vacuum Gripper attached at the tool end. Please note ONLY ONE end effector can be attached.

xArm description files, mesh files and gazebo plugin configurations, etc. It's not recommended to change the xarm description file since other packages depend on it.

Gazebo world description files and simulation launch files. User can add or build their own models in the simulation world file.

Controller configurations, hardware_interface, robot command executable source, scripts and launch files. User can deploy their program inside this package or create their own. Note that effort controllers defined in xarm_controller/config are just examples for simulation purpose, when controlling the real arm, only 'position_controllers/JointTrajectoryController' interface is provided. User can add their self-defined controllers as well, refer to: http://wiki.ros.org/ros_control (controllers)

launch files to load xarm driver to enable direct control of real xArm hardware.

Please note: xarm_moveit_config related packages will limit all joints within [-pi, pi], it seems that moveit tend to generate plans involving greater joint motions if not limited within this range. This limit can be canceled by setting "limited:=false" in ...moveit_config/launch/planning_context.launch.

This package is partially generated by moveit_setup_assistant, could use with Moveit Planner and Rviz visualization. If you have Moveit! installed, you can try the demo.

$ roslaunch xarm7_moveit_config demo.launch- If no xArm gripper needed, first run:

$ roslaunch xarm_gazebo xarm7_beside_table.launchThen in another terminal:

$ roslaunch xarm7_moveit_config xarm7_moveit_gazebo.launch- If xArm gripper needs to be attached, first run:

$ roslaunch xarm_gazebo xarm7_beside_table.launch add_gripper:=trueThen in another terminal:

$ roslaunch xarm7_gripper_moveit_config xarm7_gripper_moveit_gazebo.launchIf you have a satisfied motion planned in Moveit!, hit the "Execute" button and the virtual arm in Gazebo will execute the trajectory.

- If xArm vacuum gripper needs to be attached, just replace "gripper" with "vacuum_gripper" in above gripper example.

First make sure the xArm and the controller box are powered on, then execute:

$ roslaunch xarm7_moveit_config realMove_exec.launch robot_ip:=<your controller box LAN IP address> [velocity_control:=false] [report_type:=normal]Examine the terminal output and see if any error occured during the launch. If not, just play with the robot in Rviz and you can execute the sucessfully planned trajectory on real arm. But be sure it will not hit any surroundings before execution!

velocity_control is optional, if set to true, velocity controller and velocity interface will be used rather than position control. report_type is also optional, refer here.

First make sure the xArm and the controller box are powered on, then execute:

$ roslaunch xarm7_gripper_moveit_config realMove_exec.launch robot_ip:=<your controller box LAN IP address>It is better to use this package with real xArm gripper, since Moveit planner will take the gripper into account for collision detection.

First make sure the xArm and the controller box are powered on, then execute:

$ roslaunch xarm7_vacuum_gripper_moveit_config realMove_exec.launch robot_ip:=<your controller box LAN IP address>It is better to use this package with real xArm vacuum gripper, since Moveit planner will take the vacuum gripper into account for collision detection.

This part may require ROS Melodic or later versions to function well

For xarm5_moveit_config/xarm6_moveit_config/xarm7_moveit_config, customized tool models maybe added to the tool flange through quick-configuration parameters listed below,thus to enable Tool offset and 3D collision checking during Moveit motion planning. (Notice:configuration through '/xarm/set_tcp_offset' service will not be effective in Moveit planning!)

# attaching box model:

$ roslaunch xarm7_moveit_config demo.launch add_other_geometry:=true geometry_type:=box

# attaching cylinder model:

$ roslaunch xarm7_moveit_config demo.launch add_other_geometry:=true geometry_type:=cylinder

# attaching sphere model:

$ roslaunch xarm7_moveit_config demo.launch add_other_geometry:=true geometry_type:=sphere

# attaching customized mesh model:(Here take xarm vacuum_gripper as an example,if the mesh model could be placed in: 'xarm_description/meshes/other'directory,'geometry_mesh_filename' argument can be simplified to be just the filename)

$ roslaunch xarm7_moveit_config demo.launch add_other_geometry:=true geometry_type:=mesh geometry_mesh_filename:=package://xarm_description/meshes/vacuum_gripper/visual/vacuum_gripper.STL geometry_mesh_tcp_xyz:='"0 0 0.126"'- add_other_geometry: default to be false,indicating whether to add other geometry model to the tool.

- geometry_type: geometry shapes to be added,as one of 'box/cylinder/sphere/mesh', there are different parameters required for different types.

- geometry_height: height of geometry shape,unit: meter,default value: 0.1,effective for geometry_type: box/cylinder/sphere.

- geometry_radius: radius of geometry shape,unit: meter,default value: 0.1,effective for geometry_type: cylinder/sphere.

- geometry_length: length of geometry shape,unit: meter,default value: 0.1,effective for geometry_type: box.

- geometry_width: width of geometry shape,unit: meter,default value: 0.1,effective for geometry_type: box.

- geometry_mesh_filename: geometry shape,effective for geometry_type: mesh.

- geometry_mesh_origin_xyz: position offset from mesh base coordinate to xarm tool-flange coordinate, default: "0 0 0",effective for geometry_type: mesh.

- geometry_mesh_origin_rpy: orientation offset from mesh base coordinate to xarm tool-flange coordinate, default: "0 0 0",effective for geometry_type: mesh.

- geometry_mesh_tcp_xyz: the positional TCP offset with respect to xarm tool-flange coordinate, default: "0 0 0",effective for geometry_type: mesh.

- geometry_mesh_tcp_rpy: the orientational TCP offset with respect to xarm tool-flange coordinate, default: "0 0 0",effective for geometry_type: mesh.

This implemented simple planner interface is based on move_group from Moveit! and provide ros service for users to do planning & execution based on the requested target, user can find detailed instructions on how to use it inside xarm_planner package.

$ roslaunch xarm_planner xarm_planner_realHW.launch robot_ip:=<your controller box LAN IP address> robot_dof:=<7|6|5> add_(vacuum_)gripper:=<true|false>Argument 'robot_dof' specifies the number of joints of your xArm (default is 7). Now xarm_planner supports model with gripper or vacuum_gripper attached. Please specify "add_gripper" or "add_vacuum_gripper" argument if needed.

These two packages provide user with the ros service wrapper of the functions in xArm SDK. There are 12 types of motion command (service names) supported,please set correct robot mode first, refer to mode change section:

-

move_joint: joint space point to point command, given target joint angles, max joint velocity and acceleration. Corresponding function in SDK is "set_servo_angle()".

-

move_line: straight-line motion to the specified Cartesian Tool Centre Point(TCP) target. Corresponding function in SDK is "set_position()"[blending radius not specified].

-

move_lineb: straight-line motion, and blending continuously with next motion. Normally works in the form of a list of known via points followed by target Cartesian point. Each motion segment is straight-line with Arc blending at the via points, to make velocity continuous. Corresponding function in SDK is "set_position()"[wait=false and blending radius specified]. Please refer to move_test.cpp and blended_motion_test.py for example code,

/xarm/wait_for_finishparameter has to befalsefor successful blending calculation. -

move_jointb: joint space point to point motion, and blending continuously with next motion. It can be used together with "move_lineb" for joint-linear blending motions, as long as the via points are known, and blending radius is properly specified, velocity will be continuous during the execution. Corresponding function in SDK is "set_servo_angle()"[wait=false and blending radius specified]. Please refer to blended_motion_test.py for example code.

/xarm/wait_for_finishparameter has to befalsefor successful blending calculation. -

move_line_tool: straight-line motion based on the Tool coordinate system rather than the base system. Corresponding function in SDK is "set_tool_position()".

Please keep in mind that before calling the 4 motion services above, first set robot mode to be 0, then set robot state to be 0, by calling relavent services. Meaning of the commands are consistent with the descriptions in product user manual, other xarm API supported functions are also available as service call. Refer to xarm_msgs package for more details and usage guidance. -

move_line_aa: straight-line motion, with orientation expressed in Axis-angle rather than roll-pitch-yaw angles. Please refer to xArm user manual for detailed explanation of axis-angle before using this command.

- move_servo_cart/move_servoj: streamed high-frequency trajectory command execution in Cartesian space or joint space. Corresponding functions in SDK are set_servo_cartesian() and set_servo_angle_j(). An alternative way to implement velocity control. Special RISK ASSESMENT is required before using them. Please read the guidance carefully at examples chapter 2-3.

- velo_move_joint/velo_move_joint_timed: Joint motion with specified velocity for each joint (unit: rad/s), with maximum joint acceleration configurable by

set_max_acc_jointservice.

- velo_move_line/velo_move_line_timed: Linear motion of TCP with specified velocity in mm/s (position) and rad/s (orientation in axis-angular_velocity), with maximum linear acceleration configurable by

set_max_acc_lineservice.

- move_joint: Online joint space replanning to the new joint angles, with new max joint velocity and acceleration. Joint velocities and accelerations are continuous during transition, however the velocity profiles may not be synchronous and the final reached positions may have small errors. This function is mainly for dynamic response without self trajectory planning requirement like servo joint commands.

/xarm/wait_for_finishparameter has to befalsefor successful transition. Corresponding function in SDK is "set_servo_angle(wait=false)" under mode 6. Instructions

- move_line: Online Cartesian space replanning to the new target coordinate, with new max linear velocity and acceleration. Velocities and accelerations are continuous during transition, This function is mainly for dynamic response without self trajectory planning requirement like servo cartesian commands.

/xarm/wait_for_finishparameter has to befalsefor successful transition. Corresponding function in SDK is "set_position(wait=false)" under mode 7. Instructions

First startup the service server for xarm7, ip address is just an example:

$ roslaunch xarm_bringup xarm7_server.launch robot_ip:=192.168.1.128 report_type:=normalThe argument report_type is explained here.

Then make sure all the servo motors are enabled, refer to SetAxis.srv:

$ rosservice call /xarm/motion_ctrl 8 1Before any motion commands, set proper robot mode(0: POSE) and state(0: READY) in order, refer to SetInt16.srv:

$ rosservice call /xarm/set_mode 0

$ rosservice call /xarm/set_state 0Please note that all the angles must use the unit of radian. All motion commands use the same type of srv request: Move.srv.

To call joint space motion with max speed 0.35 rad/s and acceleration 7 rad/s^2:

$ rosservice call /xarm/move_joint [0,0,0,0,0,0,0] 0.35 7 0 0To go back to home (all joints at 0 rad) position with max speed 0.35 rad/s and acceleration 7 rad/s^2:

$ rosservice call /xarm/go_home [] 0.35 7 0 0To call Cartesian motion to the target expressed in robot BASE Coordinate, with max speed 200 mm/s and acceleration 2000 mm/s^2:

$ rosservice call /xarm/move_line [250,100,300,3.14,0,0] 200 2000 0 0To call Cartesian motion expressed in robot TOOL Coordinate, with max speed 200 mm/s and acceleration 2000 mm/s^2, the following will move a relative motion (delta_x=50mm, delta_y=100mm, delta_z=100mm) along the current Tool coordinate, no orientation change:

$ rosservice call /xarm/move_line_tool [50,100,100,0,0,0] 200 2000 0 0 Corresponding service for Axis-angle motion is MoveAxisAngle.srv. Please pay attention to the last two arguments: "coord" is 0 for motion with respect to (w.r.t.) Arm base coordinate system, and 1 for motion w.r.t. Tool coordinate system. "relative" is 0 for absolute target position w.r.t. specified coordinate system, and 1 for relative target position.

For example: to move 1.0 radian relatively around tool-frame Z-axis:

$ rosservice call /xarm/move_line_aa "pose: [0, 0, 0, 0, 0, 1.0]

mvvelo: 30.0

mvacc: 100.0

mvtime: 0.0

coord: 1

relative: 1"

ret: 0

message: "move_line_aa, ret = 0"Or

$ rosservice call /xarm/move_line_aa [0,0,0,0,0,1.0] 30.0 100.0 0.0 1 1"mvtime" is not meaningful in this command, just set it to 0. Another example: in base-frame, to move 122mm relatively along Y-axis, and rotate around X-axis for -0.5 radians:

$ rosservice call /xarm/move_line_aa [0,122,0,-0.5,0,0] 30.0 100.0 0.0 0 1 (xArm controller firmware version >= 1.6.8 required) If controlling joint velocity is desired, first switch to Mode 4 as descriped in mode change section. Please check the MoveVelo.srv first to understand the meanings of parameters reqired. If more than one joint are to move, set jnt_sync to 1 for synchronized acceleration/deceleration for all joints in motion, and if jnt_sync is 0, each joint will reach to its target velocity as fast as possible. coord parameter is not used here, just set it to 0. For example:

# NO Timed-out version (will not stop until all-zero velocity command received!):

$ rosservice call /xarm/velo_move_joint [0.1,-0.1,0,0,0,-0.3] 1 0

# With Timed-out version(controller firmware version >= 1.8.0): (if next velocity command not received within 0.2 seconds, xArm will stop)

$ rosservice call /xarm/velo_move_joint_timed [0.1,-0.1,0,0,0,-0.3] 1 0 0.2will command the joints (for xArm6) to move in specified angular velocities (in rad/s) and they will reach to target velocities synchronously. The maximum joint acceleration can also be configured by (unit: rad/s^2):

$ rosservice call /xarm/set_max_acc_joint 10.0 (maximum: 20.0 rad/s^2)(xArm controller firmware version >= 1.6.8 required) If controlling linar velocity of TCP towards certain direction is desired, first switch to Mode 5 as descriped in mode change section. Please check the MoveVelo.srv first to understand the meanings of parameters reqired. Set coord to 0 for motion in world/base coordinate system and 1 for tool coordinate system. jnt_sync parameter is not used here, just set it to 0. For example:

# NO Timed-out version (will not stop until all-zero velocity command received!):

$ rosservice call /xarm/velo_move_line [30,0,0,0,0,0] 0 1

# With Timed-out version(controller firmware version >= 1.8.0): (if next velocity command not received within 0.2 seconds, xArm will stop)

$ rosservice call /xarm/velo_move_line_timed [30,0,0,0,0,0] 0 1 0.2will command xArm TCP move along X-axis of TOOL coordinate system with speed of 30 mm/s. The maximum linear acceleration can also be configured by (unit: mm/s^2):

$ rosservice call /xarm/set_max_acc_line 5000.0 (maximum: 50000 mm/s^2)For angular motion in orientation, please note the velocity is specified as axis-angular_velocity elements. That is, [the unit rotation axis vector] multiplied by [rotation velocity value(scalar)]. For example,

# NO Timed-out version (will not stop until all-zero velocity command received!):

$ rosservice call /xarm/velo_move_line [0,0,0,0.707,0,0] 0 0

# With Timed-out version(controller firmware version >= 1.8.0): (if next velocity command not received within 0.2 seconds, xArm will stop)

$ rosservice call /xarm/velo_move_line_timed [0,0,0,0.707,0,0] 0 0 0.2This will command TCP to rotate along X-axis in BASE coordinates at about 45 degrees/sec. The maximum acceleration for orientation change is fixed.

Please Note: For no Timed-out version services: velocity motion can be stopped by either giving all 0 velocity command, or setting state to 4(STOP) and 0(READY) later for next motion. However, timed-out versions are more recommended for use, since it can be safe if network comminication or user program fails, controller firmware needs to be updated to v1.8.0 or later.

Please Note the above motion services will return immediately by default. If you wish to return until actual motion is finished, set the ros parameter "/xarm/wait_for_finish" to be true in advance. That is:

$ rosparam set /xarm/wait_for_finish trueUpon success, 0 will be returned. If any error occurs, 1 will be returned.

We provide 2 digital, 2 analog input port and 2 digital output signals at the end I/O connector.

$ rosservice call /xarm/get_digital_in$ rosservice call /xarm/get_analog_in 1 (last argument: port number, can only be 1 or 2)$ rosservice call /xarm/set_digital_out 2 1 (Setting output 2 to be 1)You have to make sure the operation is successful by checking responding "ret" to be 0.

We provide 8/16 digital input and 8/16 digital output ports at controller box for general usage.

$ rosservice call /xarm/get_controller_din io_num (Notice: from 1 to 8, for CI0~CI7; from 9 to 16, for DI0~DI7[if any]) $ rosservice call /xarm/set_controller_dout io_num (Notice: from 1 to 8, for CO0~CO7; from 9 to 16, for DI0~DI7[if any]) logic (0 or 1) For example:

$ rosservice call /xarm/set_controller_dout 5 1 (Setting output 5 [lable C04] to be 1)$ rosservice call /xarm/get_controller_ain port_num (Notice: from 1 to 2, for AI0~AI1)$ rosservice call /xarm/set_controller_aout port_num (Notice: from 1 to 2, for AO0~AO1) analog_valueFor example:

$ rosservice call /xarm/set_controller_aout 2 3.3 (Setting port AO1 to be 3.3)You have to make sure the operation is successful by checking responding "ret" to be 0.

Having connected with a real xArm robot by running 'xarm7_server.launch', user can subscribe to the topic "xarm/xarm_states" for feedback information about current robot states, including joint angles, TCP position, error/warning code, etc. Refer to RobotMsg.msg for content details.

Another option is subscribing to "/joint_states" topic, which is reporting in JointState.msg, however, currently only "position" field is valid; "velocity" is non-filtered numerical differentiation based on 2 adjacent position data, and "effort" feedback are current-based estimated values, not from direct torque sensor, so they are just for reference.

In consideration of performance, default update rate of above two topics are set at 5Hz. The report content and frequency have other options, refer to report_type argument

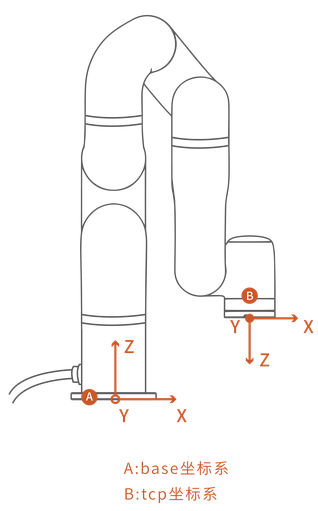

The tool tip point offset values can be set by calling service "/xarm/set_tcp_offset". Refer to the figure below, please note this offset coordinate is expressed with respect to default tool frame (Frame B), which is located at flange center, with roll, pitch, yaw rotations of (PI, 0, 0) from base frame (Frame A).

For example:

$ rosservice call /xarm/set_tcp_offset 0 0 20 0 0 0This is to set tool frame position offset (x = 0 mm, y = 0 mm, z = 20 mm), and orientation (RPY) offset of ( 0, 0, 0 ) radians with respect to initial tool frame (Frame B in picture). Note this offset might be overwritten by xArm Stdudio if it is not consistent with the default value set in studio! It is recommended to do the same TCP default offset configuration in xArm studio if you want to use it alongside with ros service control.

Sometimes controller may report error or warnings that would affect execution of further commands. The reasons may be power loss, position/speed limit violation, planning errors, etc. It needs additional intervention to clear. User can check error code in the message of topic "xarm/xarm_states" .

$ rostopic echo /xarm/xarm_statesIf it is non-zero, the corresponding reason can be found out in the user manual. After solving the problem, this error satus can be removed by calling service "/xarm/clear_err" with empty argument.

$ rosservice call /xarm/clear_errIf using Moveit!, call "/xarm/moveit_clear_err" instead to avoid the need of setting mode 1 again manually.

$ rosservice call /xarm/moveit_clear_errAfter calling this service, please check the err status again in 'xarm/xarm_states', if it becomes 0, the clearing is successful. Otherwise, it means the error/exception is not properly solved. If clearing error is successful, remember to set robot state to 0 to make it ready to move again!

If xArm Gripper (from UFACTORY) is attached to the tool end, the following services/actions can be called to operate or check the gripper.

(1) First enable the griper and configure the grasp speed:

$ rosservice call /xarm/gripper_config 1500 Proper range of the speed is from 1 to 5000. 1500 is used as an example. 'ret' value is 0 for success.

(2) Give position command (open distance) to xArm gripper:

$ rosservice call /xarm/gripper_move 500Proper range of the open distance is from 0 to 850. 0 is closed, 850 is fully open. 500 is used as an example. 'ret' value is 0 for success.

(3) To get the current status (position and error_code) of xArm gripper:

$ rosservice call /xarm/gripper_stateIf error code is non-zero, please refer to user manual for the cause of error, the "/xarm/clear_err" service can still be used to clear the error code of xArm Gripper.

The xArm gripper move action is defined in Move.action. The goal consists of target pulse position and the pulse speed. By setting "true" of "use_gripper_action" argument in xarm_bringup/launch/xarm7_server.launch, the action server will be started. Gripper action can be called by:

$ rostopic pub -1 /xarm/gripper_move/goal xarm_gripper/MoveActionGoal "header:

seq: 0

stamp:

secs: 0

nsecs: 0

frame_id: ''

goal_id:

stamp:

secs: 0

nsecs: 0

id: ''

goal:

target_pulse: 500.0

pulse_speed: 1500.0"

Alternatively:

$ rosrun xarm_gripper gripper_client 500 1500 If Vacuum Gripper (from UFACTORY) is attached to the tool end, the following service can be called to operate the vacuum gripper.

To turn on:

$ rosservice call /xarm/vacuum_gripper_set 1To turn off:

$ rosservice call /xarm/vacuum_gripper_set 00 will be returned upon successful execution.

If modbus communication with the tool device is needed, please first set the proper baud rate and timeout parameters through the "xarm/config_tool_modbus" service (refer to ConfigToolModbus.srv). For example:

$ rosservice call /xarm/config_tool_modbus 115200 20The above command will configure the tool modbus baudrate to be 115200 bps and timeout threshold to be 20 ms. It is not necessary to configure again if these properties are not changed afterwards. Please note the first time to change the baud rate may return 1 (with error code 28), in fact it will succeed if the device is properly connected and there is no other exsisting controller errors. You can clear the error and call it once more to check if 0 is returned. Currently, only the following baud rates (bps) are supported: [4800, 9600, 19200, 38400, 57600, 115200, 230400, 460800, 921600, 1000000, 1500000, 2000000, 2500000].

Then the communication can be conducted like (refer to SetToolModbus.srv):

$ rosservice call /xarm/set_tool_modbus [0x01,0x06,0x00,0x0A,0x00,0x03] 6First argument would be the uint8(unsigned char) data array to be sent to the modbus tool device, and second is the number of characters to be received as a response from the device. This number should be the expected data byte length (without CRC bytes). For example, with some testing device the above instruction would reply:

ret: 0

respond_data: [1, 6, 0, 10, 0, 3]and actual feedback data frame is: [0x01, 0x06, 0x00, 0x0A, 0x00, 0x03], with the length of 6 bytes.

When launching real xArm ROS applications, the argument "report_type" can be specified. It decides the state feedback rate and content. Refer to the developer manual at chapter 2.1.6 Automatic Reporting Format for the report contents of the three available report type (normal/rich/dev), default type using is "normal".

- For users who demand high-frequency feedback,

report_type:=devcan be specified, then the topics/xarm/xarm_statesand/xarm/joint_stateswill be published at 100Hz. - For users who want the gpio states being updated at

/xarm/controller_gpio_statestopic, please usereport_type:=rich, since this reports the fullest information from the controller. As can be seen in developer manual. - The report rate of the three types:

| type | port No. | Frequency | GPIO topic | F/T sensor topic |

|---|---|---|---|---|

| normal | 30001 | 5Hz | Not Available | Not Available |

| rich | 30002 | 5Hz | Available | Available |

| dev | 30003 | 100Hz | Not Available | Available |

Note: GPIO topic => xarm/controller_gpio_states. F/T sensor topic => xarm/uf_ftsensor_ext_states and xarm/uf_ftsensor_raw_states.

This package serves as a demo for jogging xArm with devices such as joystick.

-

- left stick for X and Y direction.

- right stick for ROLL and PITCH adjustment.

- left and right trigger (LT/RT) for Z direction.

- left and right bumper (LB/RB) for YAW adjustment.

- D-PAD for controlling joint1 and joint2.

- buttons X and B for controlling last joint.

- buttons Y and A for controlling second last joint.

# For controlling real xArm: (use xArm 6 as example) $ roslaunch xarm_moveit_servo xarm_moveit_servo_realmove.launch robot_ip:=192.168.1.206 dof:=6 joystick_type:=1 # XBOX Wired -> joystick_type=1 # XBOX Wireless -> joystick_type=2 # Or controlling real Lite6 $ roslaunch xarm_moveit_servo xarm_moveit_servo_realmove.launch robot_ip:=192.168.1.52 dof:=6 joystick_type:=1 robot_type:=lite

-

- 6 DOFs of the mouse are mapped for controlling X/Y/Z/ROLL/PITCH/YAW

- Left button clicked for just X/Y/Z adjustment

- Right button clicked for just ROLL/PITCH/YAW adjustment

# For controlling real xArm: (use xArm 6 as example) $ roslaunch xarm_moveit_servo xarm_moveit_servo_realmove.launch robot_ip:=192.168.1.206 dof:=6 joystick_type:=3 # Or controlling real Lite6 $ roslaunch xarm_moveit_servo xarm_moveit_servo_realmove.launch robot_ip:=192.168.1.52 dof:=6 joystick_type:=3 robot_type:=lite

-

# For controlling real xArm: (use xArm 6 as example) $ roslaunch xarm_moveit_servo xarm_moveit_servo_realmove.launch robot_ip:=192.168.1.206 dof:=6 joystick_type:=99 # Or controlling real Lite6 $ roslaunch xarm_moveit_servo xarm_moveit_servo_realmove.launch robot_ip:=192.168.1.52 dof:=6 joystick_type:=99 robot_type:=lite

xArm may operate under different modes depending on different controling methods. Current mode can be checked in the message of topic "xarm/xarm_states". And there are circumstances that demand user to switch between operation modes.

Mode 0 : xArm controller (Position) mode.

Mode 1 : External trajectory planner (position) mode.

Mode 2 : Free-Drive (zero gravity) mode.

Mode 3 : Reserved.

Mode 4 : Joint velocity control mode.

Mode 5 : Cartesian velocity control mode.

Mode 6 : Joint space online planning mode. (Firmware >= v1.10.0)

Mode 7 : Cartesian space online planning mode. (Firmware >= v1.11.0)

Mode 0 is the default when system initiates, and when error occurs(collision, overload, overspeed, etc), system will automatically switch to Mode 0. Also, all the motion plan services in xarm_api package or the SDK motion functions demand xArm to operate in Mode 0. Mode 1 is for external trajectory planner like Moveit! to bypass the integrated xArm planner to control the robot. Mode 2 is to enable free-drive operation, robot will enter Gravity compensated mode, however, be sure the mounting direction and payload are properly configured before setting to mode 2. Mode 4 is to control arm velocity in joint space. Mode 5 is to control arm (linear) velocity in Cartesian space. Mode 6 and 7 are for dynamic realtime response to newly generated joint or Cartesian target respectively, with automatic speed-continuous trajectoty re-planning.

If collision or other error happens during the execution of a Moveit! planned trajectory, Mode will automatically switch from 1 to default mode 0 for safety purpose, and robot state will change to 4 (error state). The robot will not be able to execute any Moveit command again unless the mode is set back to 1. The following are the steps to switch back and enable Moveit control again:

(1) Make sure the objects causing the collision are removed.

(2) clear the error:

$ rosservice call /xarm/clear_err(3) switch to the desired mode (Mode 2 for example), and set state to 0 for ready:

$ rosservice call /xarm/set_mode 2

$ rosservice call /xarm/set_state 0For simple demonstrations of vision application development with xArm, including hand-eye calibration and object detection and grasping. Examples are based on Intel RealSense D435i depth camera.

First enter the workspace source directory:

$ cd ~/catkin_ws/src/Please refer to the installation steps at official webpage.

Refer to official Github:

$ git clone -b kinetic-devel https://github.com/pal-robotics/aruco_ros.gitRefer to official Github:

$ git clone https://github.com/IFL-CAMP/easy_handeyeRefer to official Github:

$ git clone -b kinetic-devel https://github.com/lagadic/vision_visp.gitRefer to official Github:

$ sudo apt-get install ros-kinetic-find-object-2d$ cd ~/catkin_wsThen follow chapter 4.3.

$ catkin_makeIf attaching RealSense D435i camera at tool end of xArm, with mechanical adapters, making a "eye-on-hand"(or eye-in-hand) configuration,the following launch file can be used and modified for hand-eye calibration: (make sure the camera communication is functional and robot is properly switched on)

$ roslaunch d435i_xarm_setup d435i_xarm_auto_calib.launch robot_dof:=your_xArm_DOF robot_ip:=your_xArm_IPThe aruco Marker used inside can be downloaded here, please remember the marker ID and marker size and modify them in the launch file accordingly. Refer to officialor other usage instructions online and finish the calibration with the GUI.

If calculation result is confirmed and saved,it will appear by default under ~/.ros/easy_handeye directory and can be used for transferring object coordinates to base frame. If the camera_stand provided by UFACTORY is used for fixing camera, a sample calibration result is stored at xarm_vision/d435i_xarm_setup/config/xarm_realsense_handeyecalibration_eye_on_hand_sample_result.yaml for this case.

Please first read through the above instruction for xarm series, and use the files listed here for Lite6 calibration.

Sample calibration launch:

$ roslaunch d435i_xarm_setup d435i_lite6_auto_calib.launch robot_ip:=your_xArm_IPSample Calibration result file: lite6_realsense_handeyecalibration_eye_on_hand_sample_result.yaml

Sample calibration result TF publication: publish_handeye_tf_lite6.launch

find_object_2d is used for this demo for simple object detection and grasping. Hardware used in this part: RealSense D435i depth camera, UFACTORY camera stand and the xArm Gripper.

1.Use moveit to drive xArm's motion,recommended for singularity and collision free execution, but will require a reliable network connection.

$ roslaunch d435i_xarm_setup d435i_findobj2d_xarm_moveit_planner.launch robot_dof:=your_xArm_DOF robot_ip:=your_xArm_IPIf target object can be properly detected, to run the Grasping node:

$ rosrun d435i_xarm_setup findobj2d_grasp_moveitPlease note it will use previously mentioned sample handeye calibration result, you can change it at publish_handeye_tf.launch. For node program source code, refer to: d435i_xarm_setup/src/findobj_grasp_moveit_planner.cpp.

2.Alternatively, to drive xArm motion with ros service provided by 'xarm_api', in this way, real-time performance of network will not be required so strict as moveit way, but execution may fail in the middle if singularity or self-collision is about to occur.

$ roslaunch d435i_xarm_setup d435i_findobj2d_xarm_api.launch robot_dof:=your_xArm_DOF robot_ip:=your_xArm_IPIf target object can be properly detected, to run the Grasping node:

$ roslaunch d435i_xarm_setup grasp_node_xarm_api.launchPlease note it will use previously mentioned sample handeye calibration result, you can change it at publish_handeye_tf.launch. For node program source code, refer to: d435i_xarm_setup/src/findobj_grasp_xarm_api.cpp.

Please read and comprehend the source code and make necessary modifications before real application test, necessary modifications include preparation pose, grasping orientation, grasping depth, motion speed and so on. The identification target name in the code is "object_1", which corresponds to 1.png in /objects directory, users can add their own target in "find_object_2d" GUI, then modify the source_frame inside the code, for costomized application.

Tips: make sure the background is clean and the color is distinguished from the object, detection success rate can be higher if the target object has rich texture (features).

For installation with camera stand provided by UFACTORY, the cam model can be attached by following modifications (use xarm7 as example):

1.Together with xArm Gripper model: Set add_realsense_d435i default value to be true in xarm7_with_gripper.xacro.

2.Together with xArm Vacuum Gripper model: Set add_realsense_d435i default value to be true in xarm7_with_vacuum_gripper.xacro.

3.Purely the d435i: Set add_realsense_d435i default value to be true in xarm7_robot.urdf.xacro.

# enter source directory of ROS workspace:

$ cd ~/catkin_ws/src/

# Download through git (mind to checkout the proper branch):

$ git clone https://github.com/JenniferBuehler/gazebo-pkgs.git

$ git clone https://github.com/JenniferBuehler/general-message-pkgs.git

# Compile:

$ cd ..

$ catkin_make # Initialize gazebo scene and move_group:

$ roslaunch xarm_gazebo xarm_camera_scene.launch robot_dof:=6

# In another terminal, run the color recognition and grasping script:

$ rosrun xarm_gazebo color_recognition.py # launch move_group:

$ roslaunch camera_demo xarm_move_group.launch robot_ip:=192.168.1.15 robot_dof:=6

# In another terminal, run the color recognition and grasping script (use with interaction prompt):

$ rosrun camera_demo color_recognition.pyThere are some other application demo examples in the example package, which will be updated in the future, feel free to explore it.