The non-uniform stress / strain accross a balloon's surface is of interest for superpressure balloon design. Additionally the technique of "pre-stretching" can be used to modify the balloon's surface stress distribution.

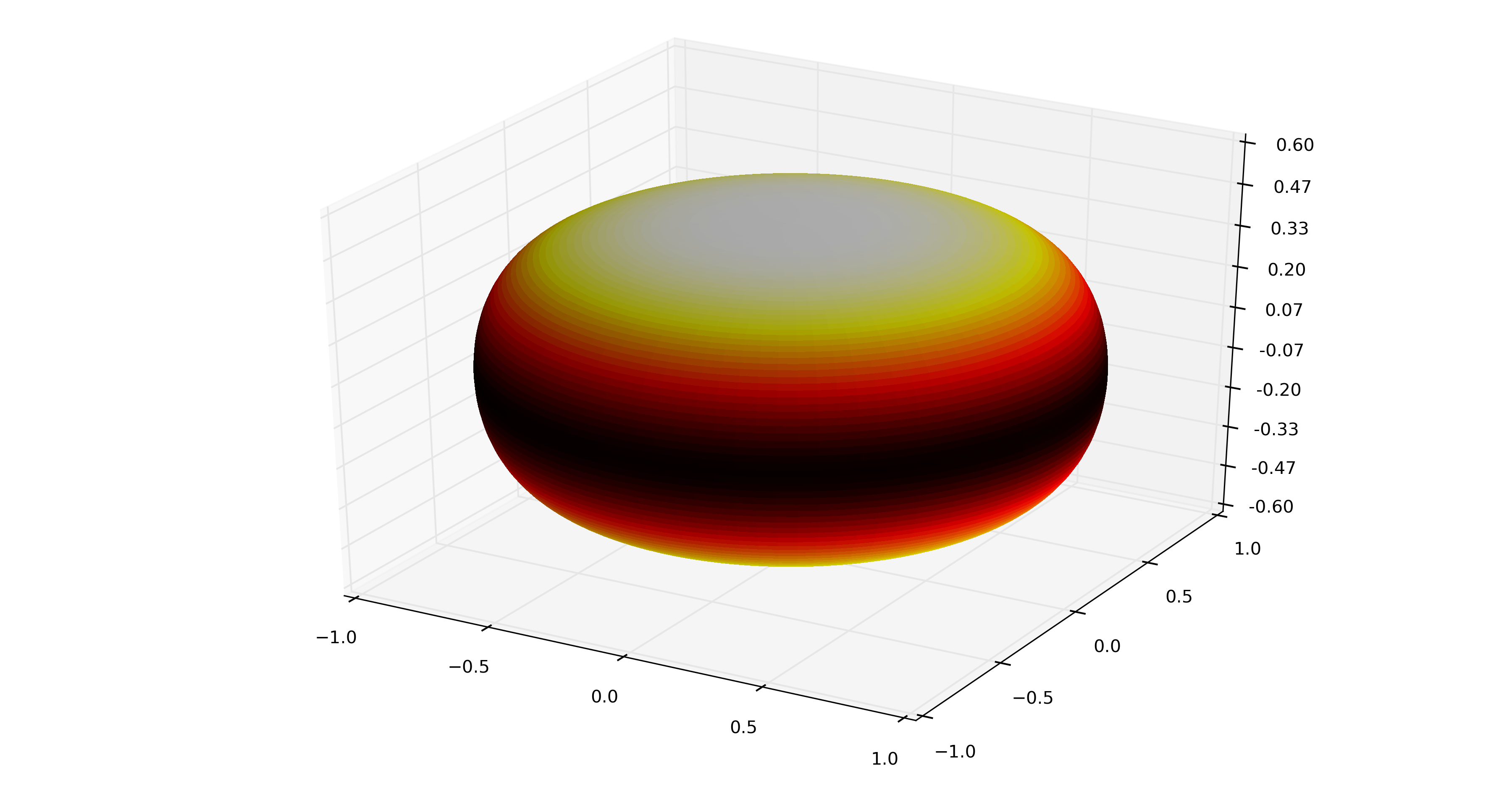

Example plot of stress in a mylar balloon shape, before pre-stretching

However the understanding of this process, especially for the mylar balloon shape popular among amateurs for its simplicity, has not developed much beyond alchemy. At least in part this is due to a lack of data and repeatable experiments, and difficulties in controlling external variables given that some experiments last for 10s of hours.

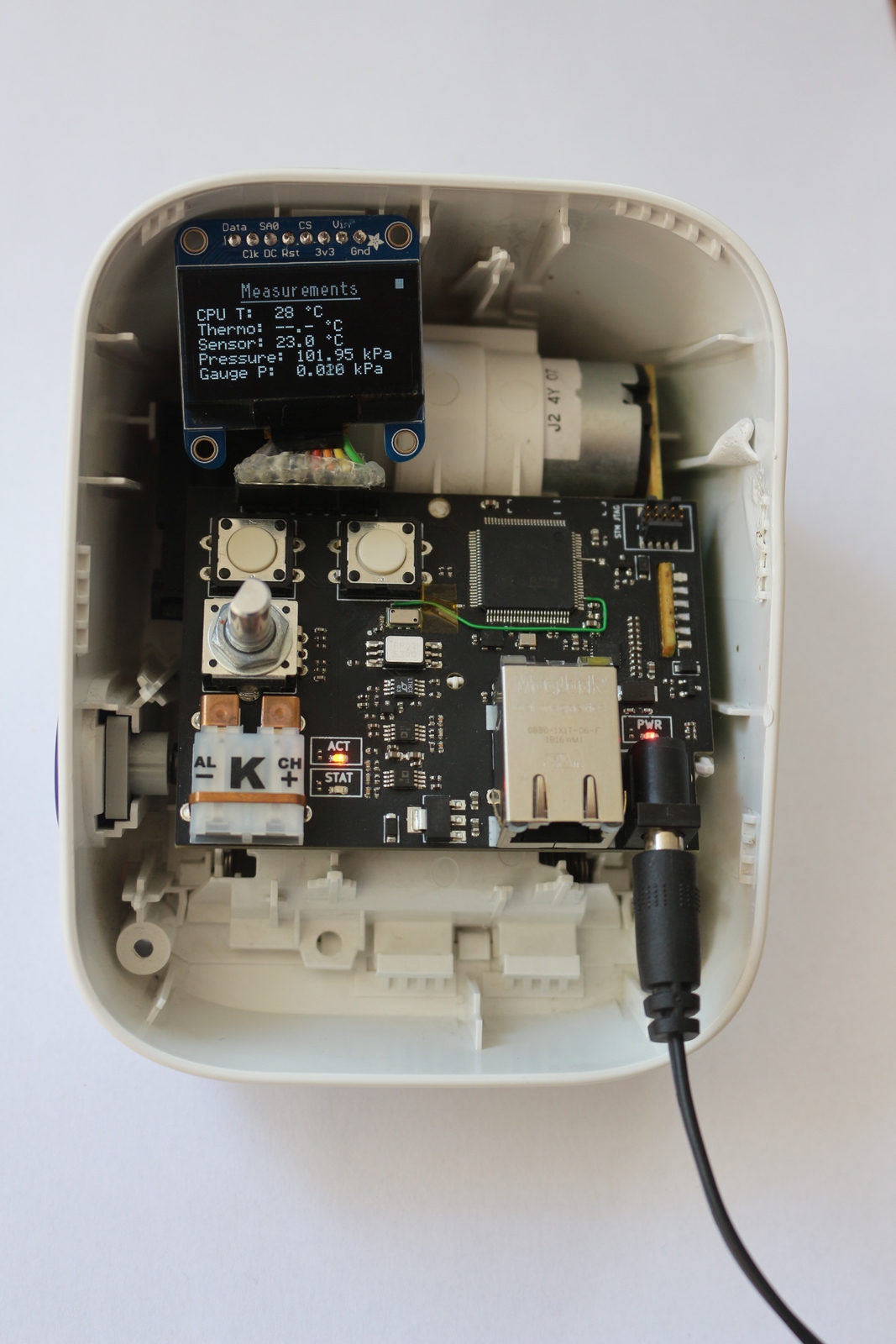

Alakol is a specialised datalogger for collecting data about the pre-stretching process. It measures:

- Gauge pressure the difference in pressure between inside the balloon envelope and outside

- Ambient temperature using a K-Type thermocouple

- Absolute ambient pressure which can be used to remove any effect from ambient pressure changing over time

- Board Temperature used as the cold-junction temperature for the thermocouple and also useful for calibrating the gauge pressure measurement against temperature

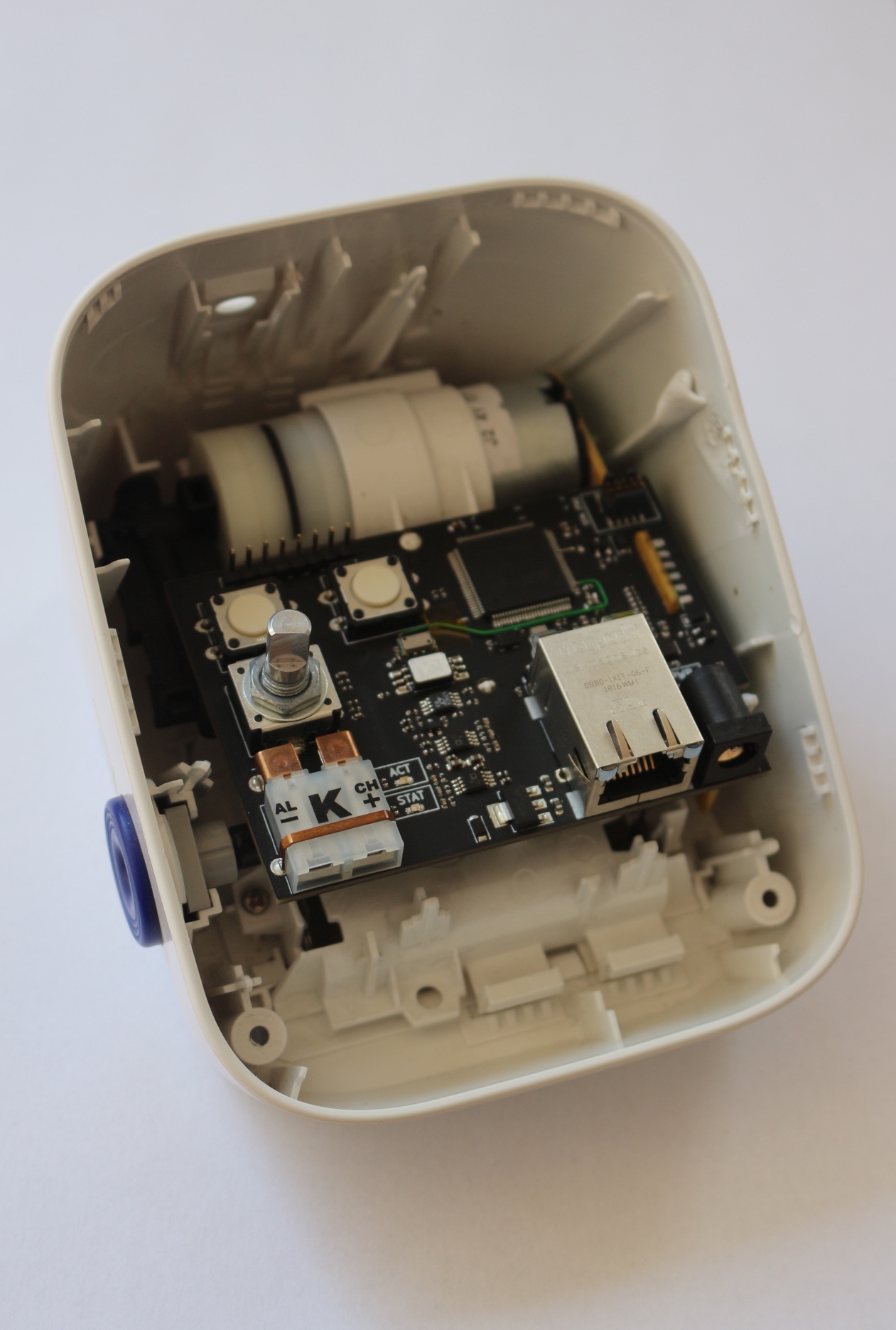

The Alakol re-uses the mechanical elements from an Omron M2 Blood Pressure Monitor (BPM). It can pump ambient air into a +ve pressure up to ~40kPa at a (roughly) constant rate, and then release this pressure via a solenoid controlled valve. This is not the first superpressure balloon project to re-use the Omron M2 BPM (was this Leo?) but it takes the additional step of building a datalogger around it.

🚧🚧🚧🚧 WARNING: The Omron M2 Blood Pressure Monitor is a consumer medical device, but after the modifications described here it is no longer suitable for its original purpose nor should it be used on people (or anything alive really). Before modifying an Omron M2 you must ensure it is surpless to any medical requirements, and that it is clearly marked as non-medical. After modification the original display panel will no longer fit, which ensures the extent of the modification is abundantly clear to anyone. The Ormon M2 can usually be purchased off the shelf at consumer stores. 🚧🚧🚧🚧🚧

Project Goals:

- Measure all of the obvious enviromental variables.

- Be pleasant to use.

Not a Goal:

- Be very low cost.

The hardware is a 1.6mm thick 4-layer PCB that replaces all of the internal PCBs in the M2, except from the motor / value breakout PCB (which has no components anyhow).

The hardware is designed in KiCad. See the hardware directory.

The firmware runs on a STM32 microcontroller, and is written in Rust. See the firmware directory.

A small OLED display displays measurements, and a very simple user interfaces allows you to cycle between screens, control the motor and valve, and zero the gauge pressure reading.

Over Ethernet, it offers a HTTP server for commanding the motor and valve, whilst a separate TCP server on port 8080 streams the measurement data at a 10Hz update rate.

There are some python scripts. See the software directory.

See each section (hardware/firmware/software).