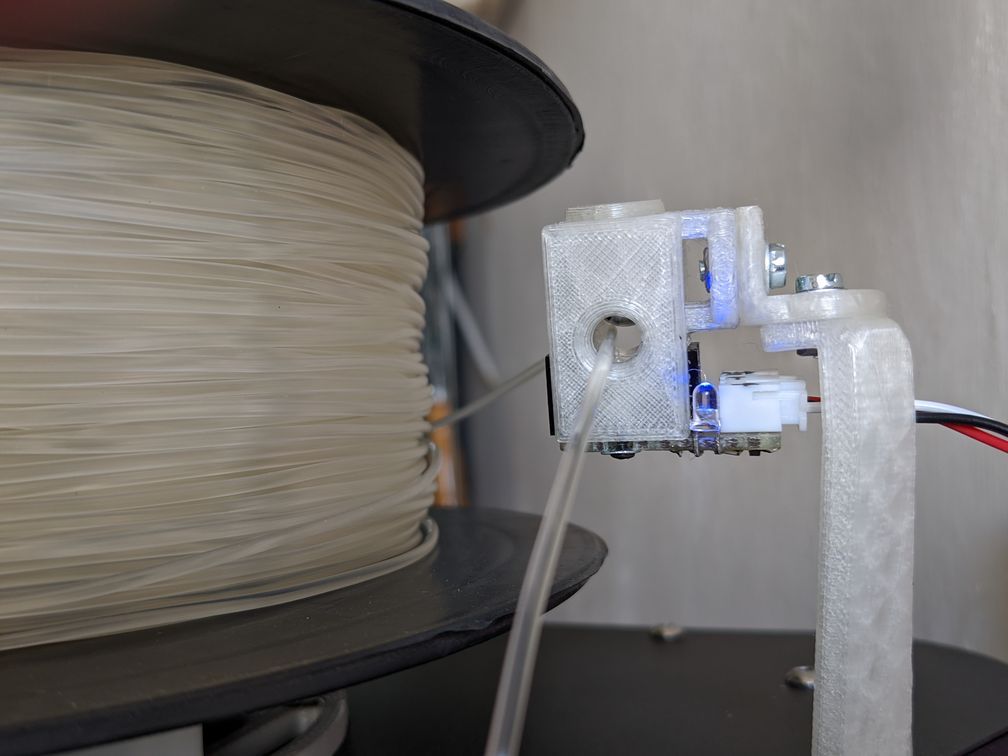

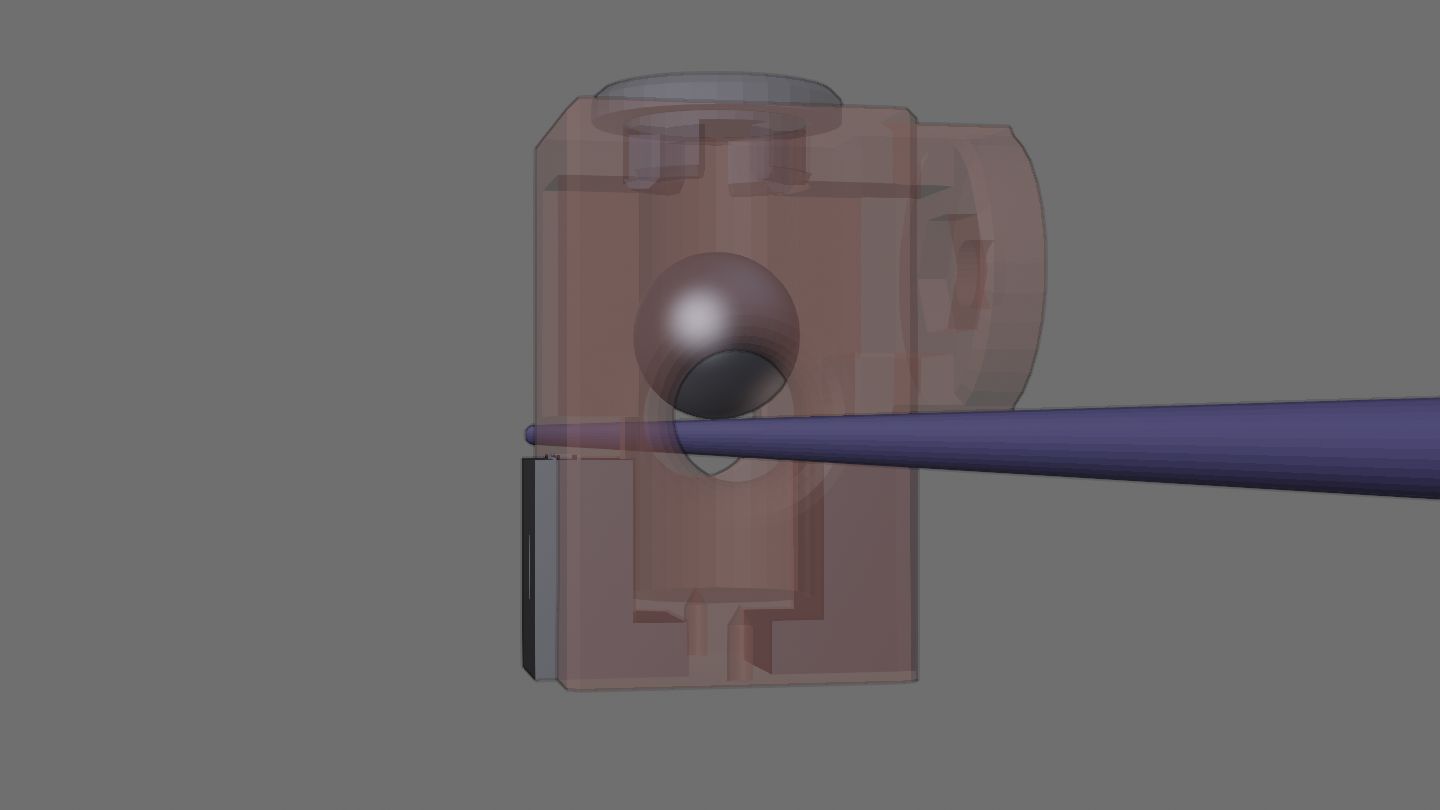

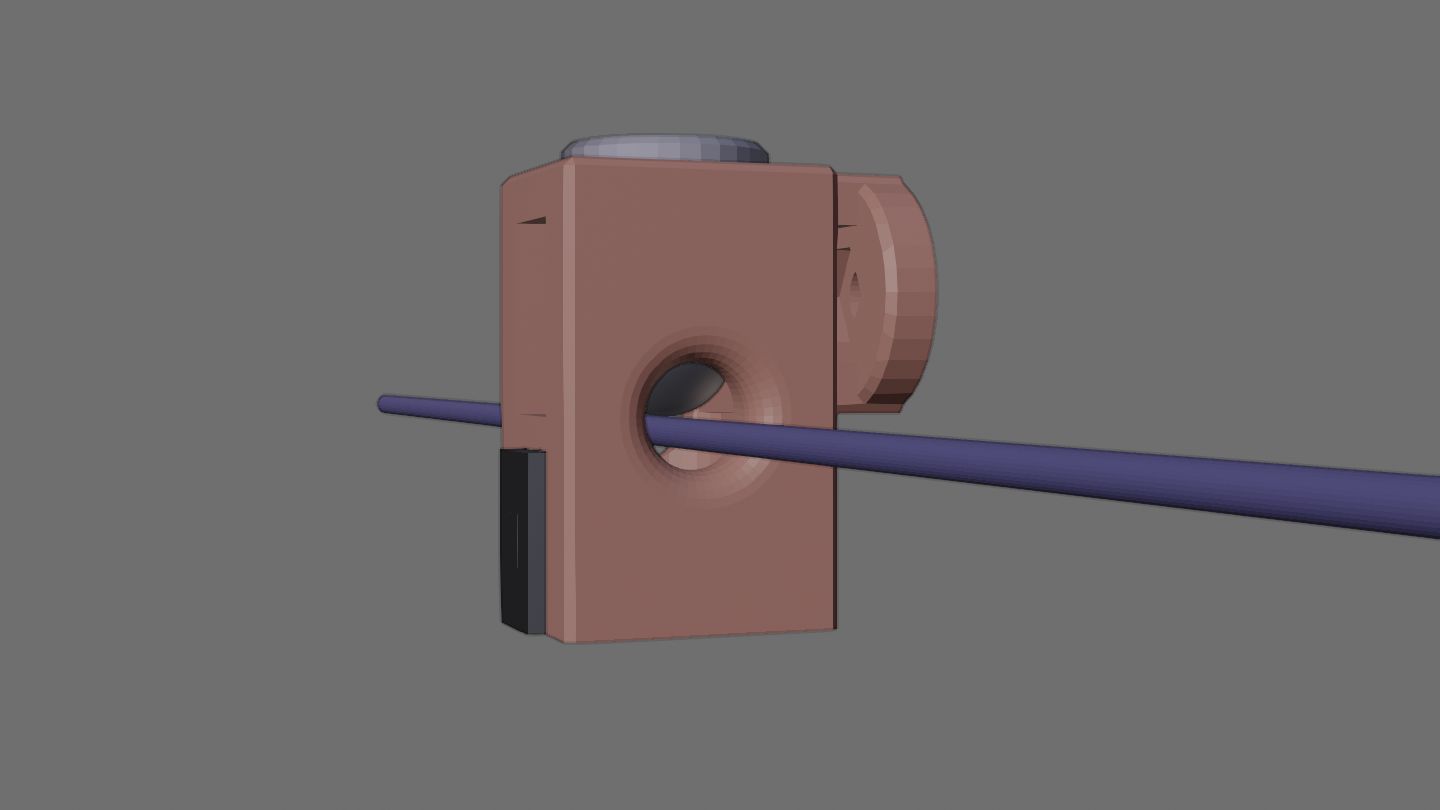

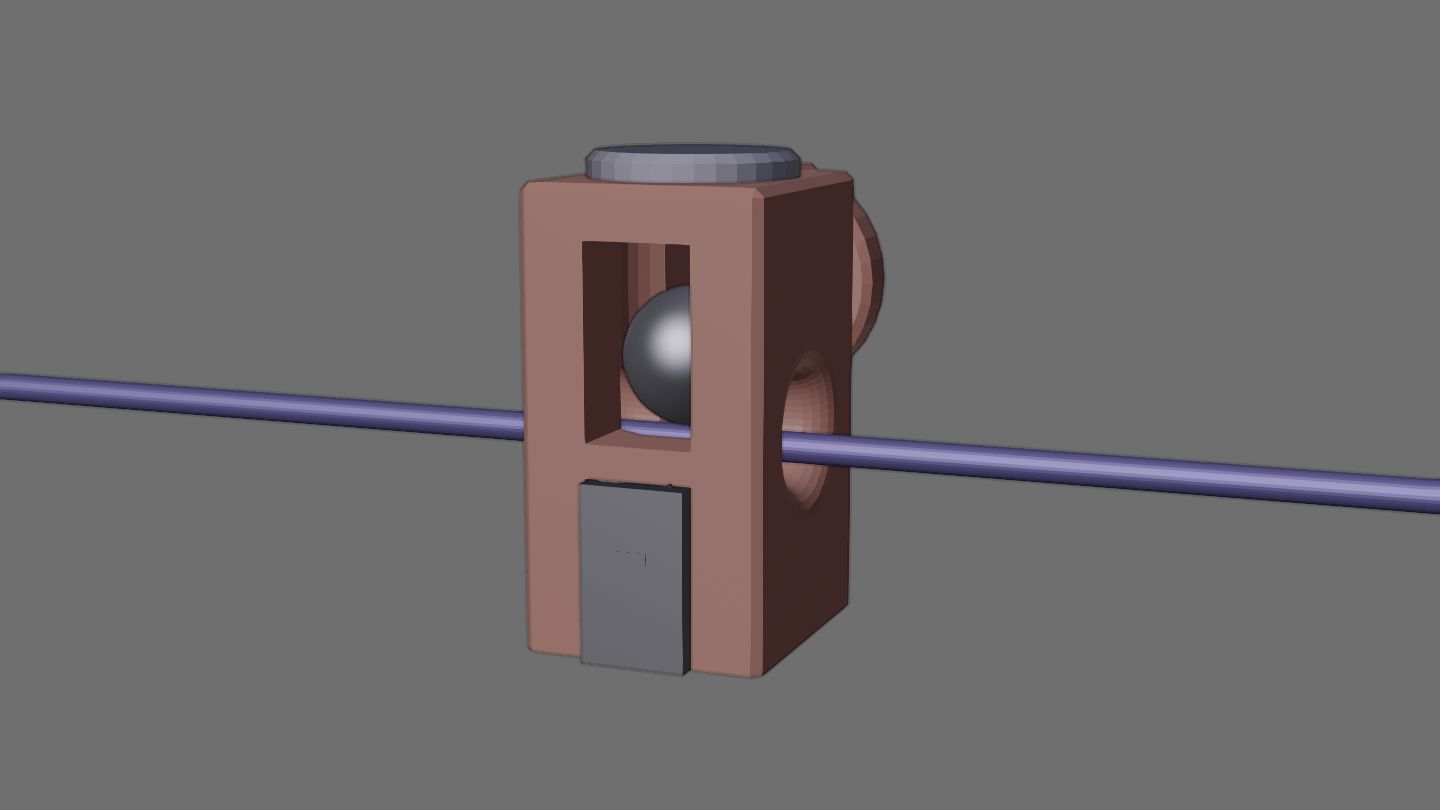

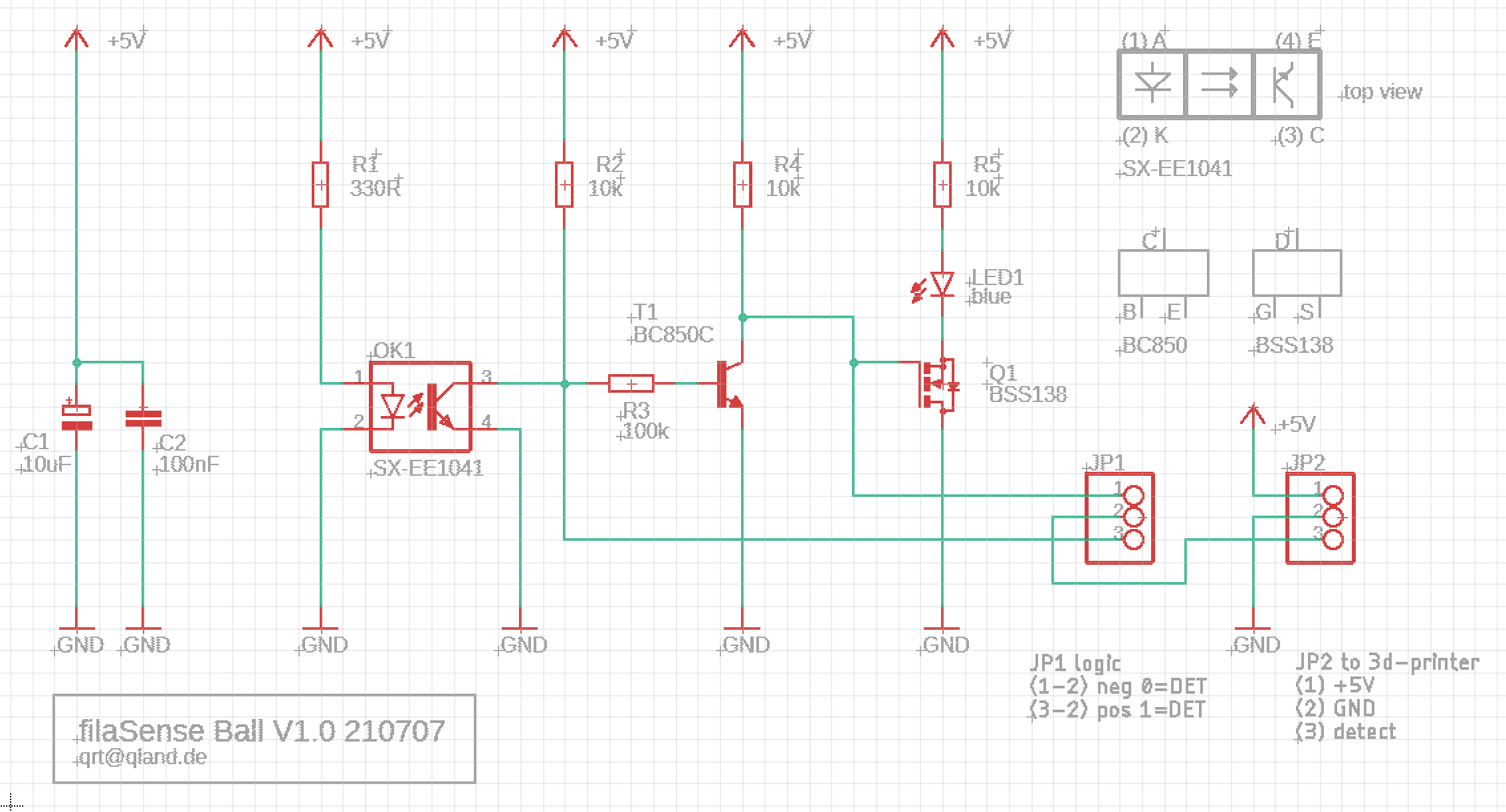

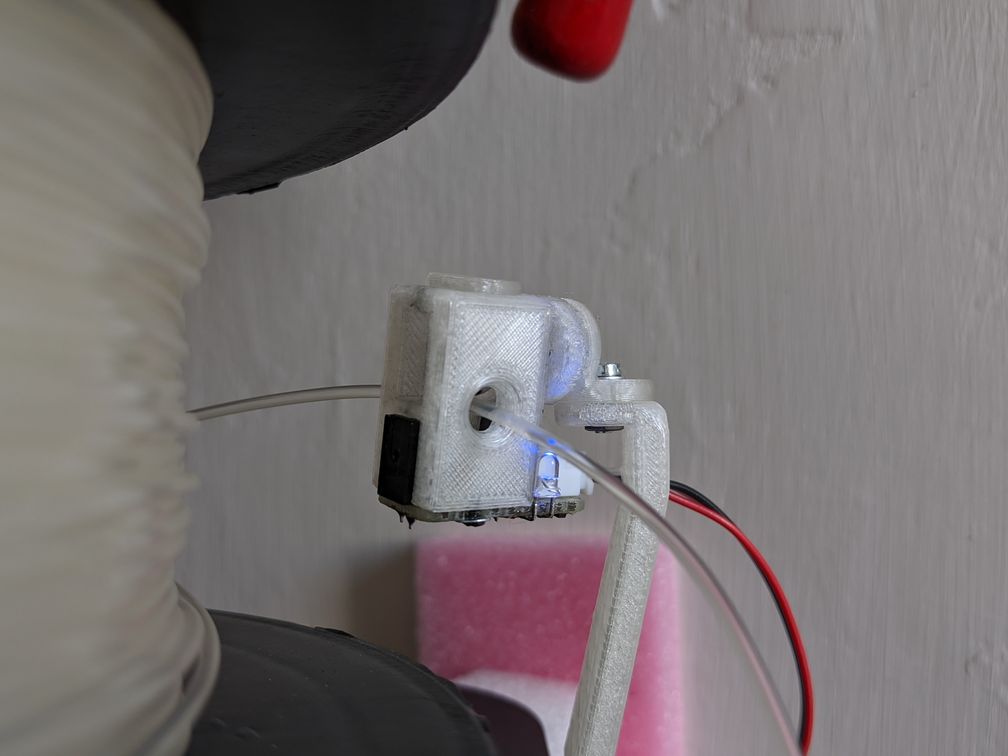

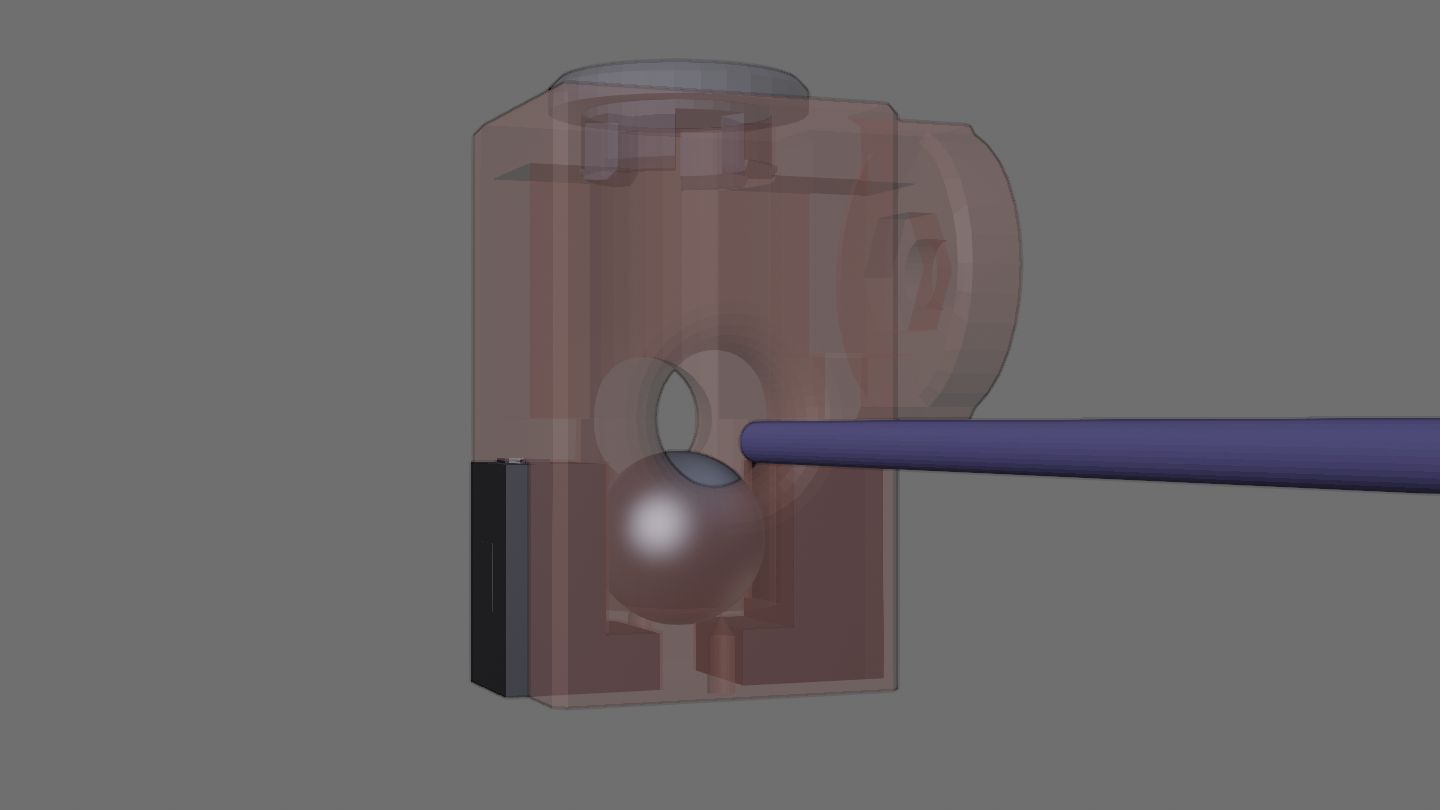

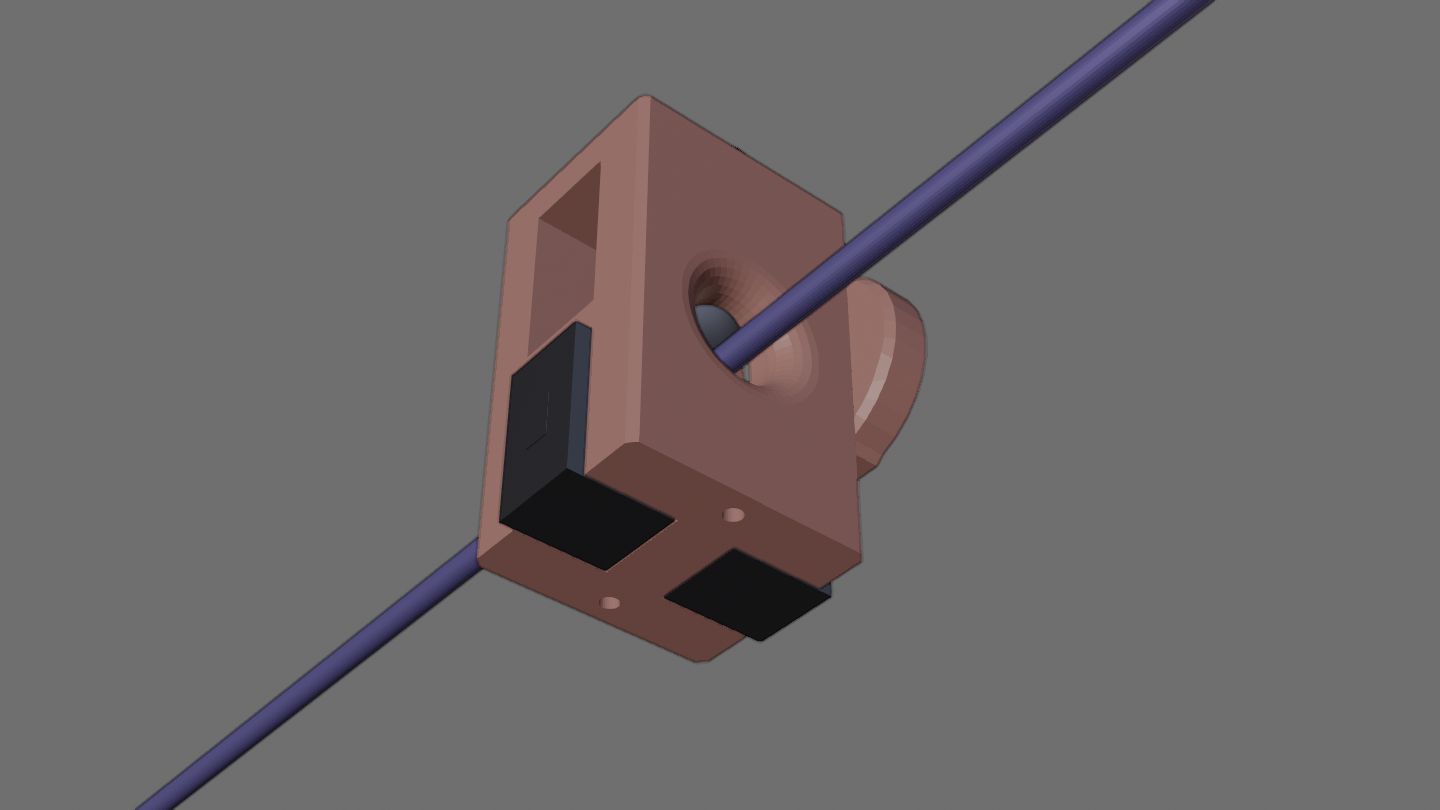

A steel ball is caught above the filament and drops into a light barrier if filament runs out. To reload filament a magnet is used to lift the steel ball. A cap allows closing and opening the housing.

Filament state is indicated by LED

- on

loaded - off

runout

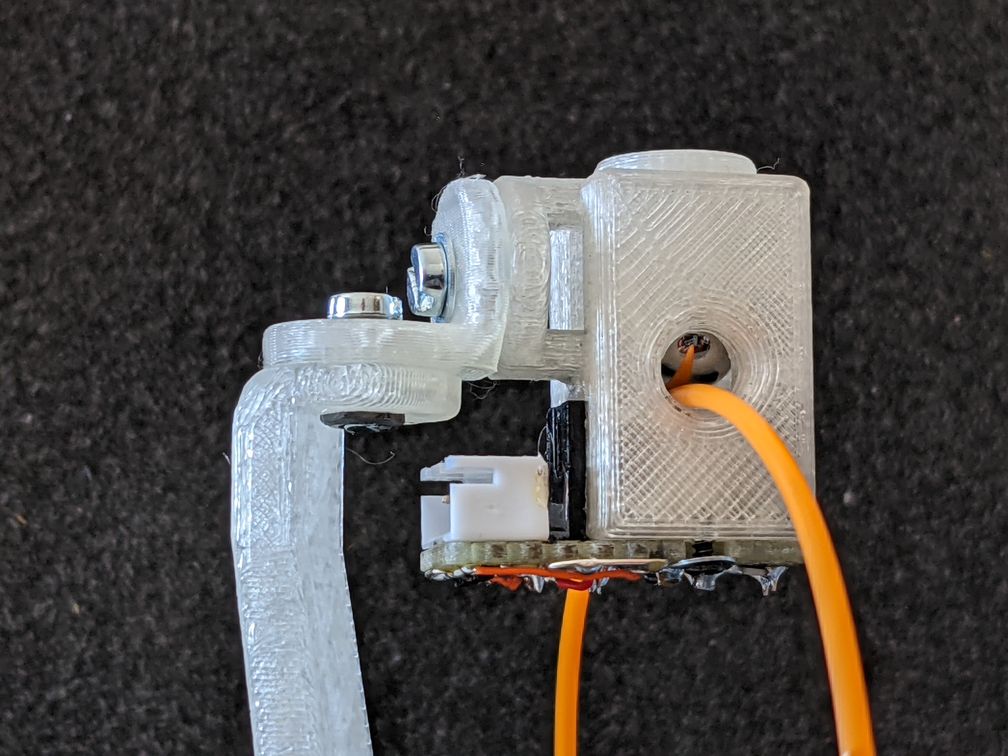

The three housing parts are printed flat sides down with support enabled at about 20 % fill rate. After printing the housing halves are glued together with hard plastic glue or superglue and the seams welded with a soldering iron (at about 200 °C for PLA). The fork light barrier is cut in half and plugged into the housing bottom. A suitable piece of perforated or drilled PCB is soldered to the light barrier leads. The PCB can be screwed to the little holes on the housing bottom. The little holes may need careful re-drilling according to the used screws. Electronic components, LED and printer connector are now soldered on the PCB. An 8 mm steel ball is put into the housing, the printed cap snap-closes it.

-> 3d print

q5 prefix files are tailored for Flsun delta printer Q5

https://www.thingiverse.com/thing:4902782

To adapt to filament tension the sensor can be tilted

if smoothly printed a tilt angel up to 85 degree should be possible

A mounting bracket allows adjusting tilt and top angle

Steel ball dropped into light barrier

Bottom with light barrier halves

qrt@qland.de 210716