I’m not an expert and 3D printing is just my hobby. So please be careful when you build this mod and don’t just go ahead. All parts are tested and working. But everybody bears the risks of a modification him/herself! I'm not responsible if any harm occurs, so be careful, especially with the knife!

EREC

BOM

Assembly

Firmware

Showroom

Acknowledgements

Changelog

This is a simple filament cutter for the awesome ERCF so tip tuning is less important.

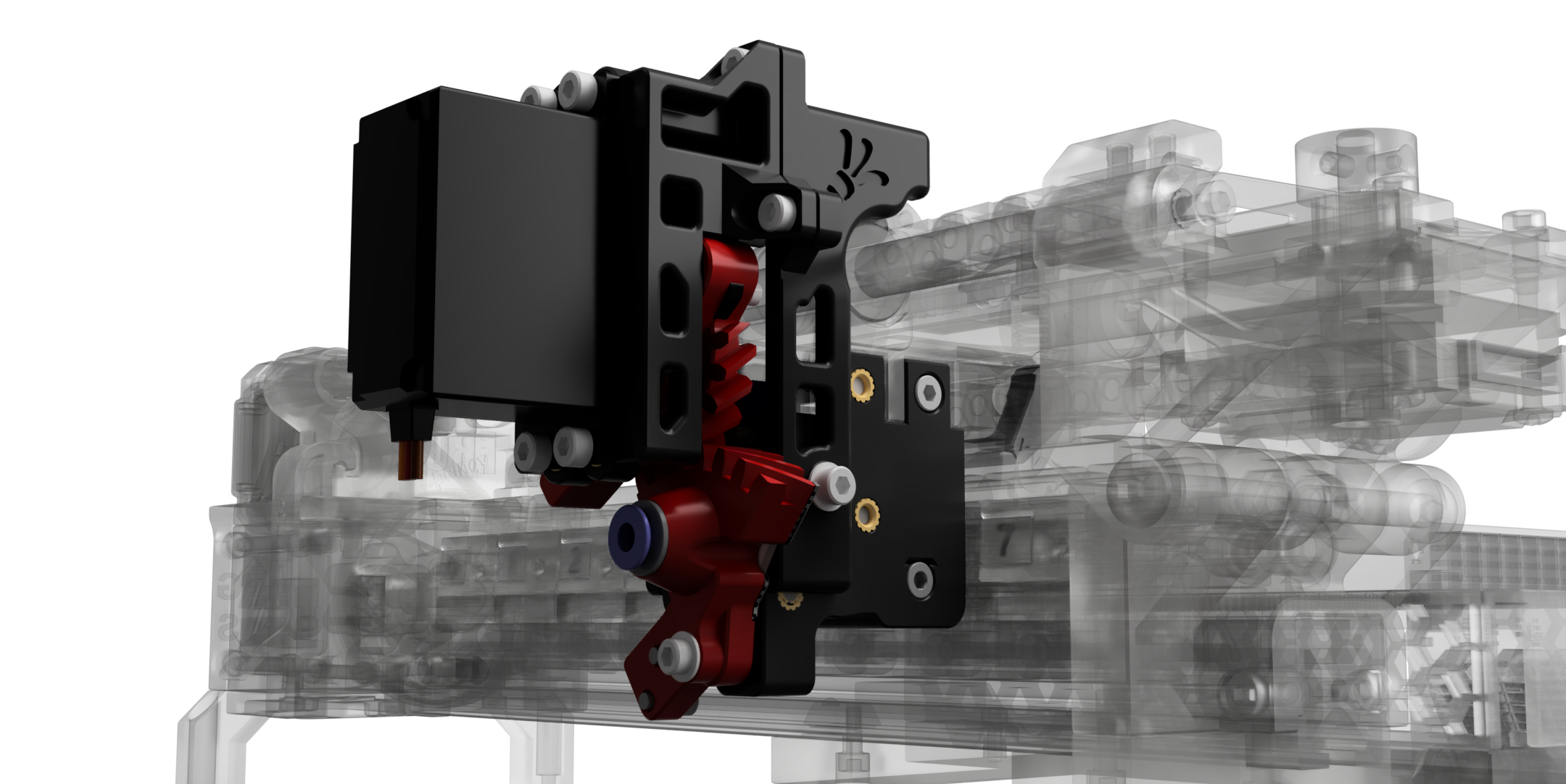

It's made out of a Servo and a scalpell/exacto knife blade. The cutter get's mouted to the selector chart just behind the encoder - the cutter is basically an arm that swings to the left and right. Since the ECAS sits now on the Arm the filament path can be opened by swining the arm to the side. Then the ERCF can feed some filament mid air (the filament tip) and when the arm swings back to close the filament path the tip gets cut off by the knife on the arm. The cut off tip just falls off to the ground and the filament can be loaded with a clean tip the next time.

I never thought about a filament cutter untill I saw the Filametrix design / got it recommended. Since I'm not using the ERCF with a Stealthburner (for now at least) I would have to make a cutter on my own. At the same time u/BioKeks requested a cutter for my Ender 3 fan duct (Frankenstein 2.0) and that way I though we need something universial. After some days of tinkering this was the result - first with the MG90s servo, but that was so weak it was far aways from cutting it. So long speech short, thanks to sorted01 for the idea with the cutter!

Considering my other ongoing projects, I’ve decided to appoint u/BioKeks as the new primary contributor to this project. Don’t worry, I’m not completely stepping away, but if you have any questions, feel free to ask u/BioKeks!

| Qty | Part | Description |

|---|---|---|

| 1 | Servo MR996 | That's just the servo I use, nothing special. But the MG90S are definetly too weak. 60° may work, but I highly recommend getting at least a 90° servo. Also check the torque, u/BioKeks was't able to cut soft PLA with a 12kg.cm servo |

| 1 | Exacto knife blade No. 11 | That's just an example so you know the shape/type. Higher quality blades probably last longer. |

| 1 | 5V buck converter | The Servo can take quite a lot of current, enough to shut down my ERCF board. If you have the same problem try a buck converter wired to the PSU or use your dedicated 5V PSU |

| 10 | M3 Threaded Insert | Just the same inserts you already used during the ERCF assembly 😉 |

| 1 | M3 lock nut | To prevent the screw on the cutter_arm to be loosened over time |

| 3 | M3 washer | Use some washers to screw in the cutter_arm and the servo_hinge_mount |

| 1 | M3x18 SHCS | Used to mount the cutter arm |

| 4 | M3x6 SHCS | These are used to mount the servo motor on the printed part |

| 1 | M3x6 BHSC | This screw comes usually with your servo motor, its used to mount the servo_arm on the servo. SHCS probably works also |

| 2 | M2.5x6 SHCS | To mount the knife to the arm you will need some M2.5 screws, it doesn't matter if they are longer than 6mm. Pro tip: Check out your hotend assembly kit, it often ships with some M2.5 screws |

| 4 | M2x6 SHCS | These screws are used to lock the servo attachment with the printed part. Screw length can vary a bit, if you don't have any laying around I recommend getting a cheap M2-Screw kit on AliExpress |

|

The assembly process is straightforward; I’ve tried my best to keep it simple. If you need any help, feel free to join our discord server.

|  |

Thanks to...

-

BioKeks for tinkering with me! Luckily we both got the ERCF roughly at the same time :D

-

xF4m3 for the Macro help!

-

sorted01 for the idea with the cutter!

-

moggieuk for the awesome firmware and the quick help on the Voron Discord!

And of course thanks to EtteGit and the amazing ERCFV2 Team for the awesome EnragedRabbitProject!

- Adaption of the Binky encoder for the cutter - made by u/BioKeks

- Fixed an overhang issue with the

Servo_Mount.stl

01/10/2023: Triple-Decky Support

- Adaption of the Binky encoder for the 3PS version - made by u/BioKeks

- Improved bowden tube fit by adjusting the encoder - Thanks for the feedback u/xF4m3

- Fixed an overhang issue with the

Encoder_Cart_Left.stl- made by u/BioKeks

- Overhauled the cutter design for more cutting power and reliability

- Adaption of the Binky encoder for Beta5 - made by u/BioKeks

- Adaption for the new ERCF2.0 Encoder - made by u/BioKeks

NOTE: Beta6 drops support for the old ERCFV1