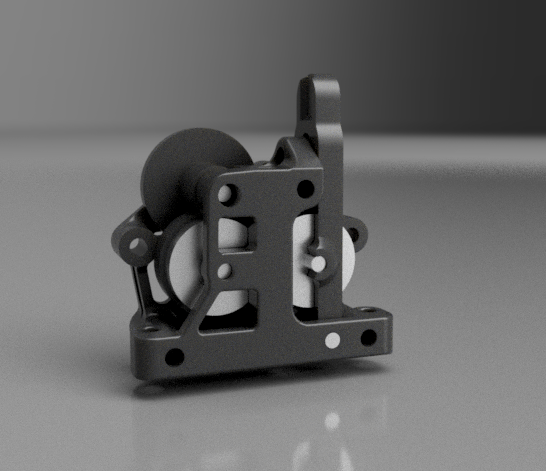

Heavily inspired by the Sherpa Mini by Annex Engineering

Same attachment spacing and filament path as the Sherpa Mini therefore you can reuse your current tool mount along with PTFE tubes.

-

4x M3x5x4mm heat inserts

-

2x M3x12mm ISO 7380 button head screws

-

3x M3x25mm ISO 7380 button head screws

-

Bondtech BMG Thumbscrew Tensioner

-

Latch Arm axle:

- 3x20mm dowel pin

or

- 1x M3x5x4mm heat inserts

- 1x M3x25mm ISO 7380 button head screw

Either scavenge the LGX or LGX lite for parts or:

- 1x LGX® Primary Gear

- 2x LGX® Secondary Gear

- 2x LGX® Hardened Steel Drive Wheel

- 2x Needlebearing

- 2x 3x16mm dowel pins

- 1x 3x20mm dowel pin

1x Nema 14 36mm Pancake Stepper - 10T (T=Teeth) or 8T it's up to you, good choices are high temp models:

- MOONS' CSE14HRA1L410A

- LDO-36STH17-1004AHG

The model is prepared for using 4 (+one optional for Latch Arm axle using screw instead of pin) M3x5x4 heat inserts. They can be brought in any decent 3d printing eshop (eshops selling parts for Voron usually sells these).

Latch Arm combined with Thumbscrew Tensioner should provide enough of grip on filament. However the latch frame is thin arounfd the gearings (design issue) and could break. Solutions (in order of success):

- Print the Latch Arm from filament enriched with CF (I am using Prusament PC CF with great success).

- Aneal it after printing to further improve layer bonding.

- You cound try to print it rotated by 90° (requires supports) thus the layers are positioned perpendicular to tensioning force.

Use ABS or ASA if posssible. It depends on whever you will be using the Extruder. PLA or PETG is not suitable in enclosed chamber. Or even better use PC CF (see info above). The STL's are already oriented for you, so you only need to send them to the slicer. There is no need for supports; recommended settings are 4 perimeters/top/bottom, at least 30% infill. You might consider rotating 90° the Latch Arm to combat the issue mentioned in Notes.

See the assembly.md.