This project contains two parts:

- Simulation of the picking process.

- Heuristic for optimization of batching and ordering.

Each picker have to pick a list of items from the pick faces. The list of items referred as a batch.

The moving of the pickers is discrete and dependent on their direction. The last picker picks till he finish to pick all the items in his batch. When he finish he starts to walk backwards until he "meet" the picker behind him, he transfer the batch to the last picker, and walks backwards and so on...

The process ends when all the batches have been picked.

The moving and item picking durations are sampled from a normal distributions with different means and variances which depends on the picker. So the process is Stochastic.

Input - List of orders

Challenge - Batching the orders and ordering the batches

Objective - Minimization of the picking time.

The suggested heuristic divides the problem into two classic, well studied combinatorial optimization problems:

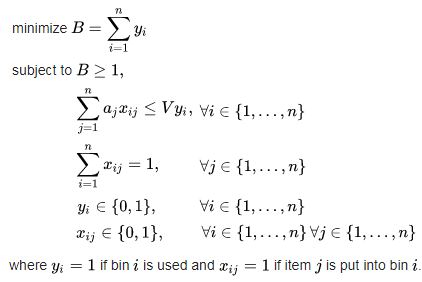

The task of batching can be solved optimally with the well known Bin packing problem.

The problem formulated in Wikipedia as:

In the context of batching the bins represents batches, subject to the maximal number of items that a picker can pick on a single batch.

the problem formulated on python and solved as a linear programming problem. with a timeout of 5 minutes.

TSP is probably one of the most famous problems, however it's relation to the batch ordering problem is not trivial.

The intuition to use TSP came from the assumption that: subsequent batches should be similar as much as possible.

There is no proof to this assumption, but it sounds reasonable since "gaps" between subsequent batches may lead to "gaps" between pickers - greater walking distance..

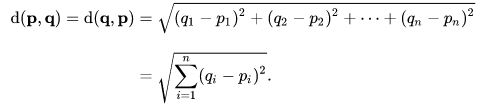

So the idea is to model each batch as a city in the TSP problem and each pick face as a dimension.

It will produce n-dimensional TSP problem, we can also relax the constraint that the route should be cyclic, since it doesn't matter here.

The most intuitive is the euclidean distance:

Since the meaning of distance in this context is tentative, we are not limited to the euclidean distance...

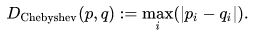

Better understanding of the dynamics in the picking process may lead to choose different distance metrics, like Chebyshev distance:

which will take into account only the dimension (pick face) with the greatest difference or the "bottle neck" between two batches.

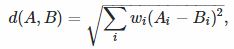

Less "radical" metric could be a weighted euclidean metric:

By tuning the set of weights, different pick faces can be prioritized.

| pick faces | pickers | capacity | data | random order | euclidean | chebyshev |

|---|---|---|---|---|---|---|

| 6 | 2 | 60 | a | 80.8458 | 86.7586 | 87.3944 |

| 6 | 2 | 90 | a | 65.5462 | 62.0748 | 64.0948 |

| 6 | 2 | 60 | b | 68.698 | 70.787 | 67.5055 |

| 6 | 2 | 90 | b | 52.5133 | 51.8276 | 50.5389 |

| 10 | 2 | 100 | a | 423.1702 | 426.9223 | 423.4411 |

| 10 | 3 | 100 | a | 248.6059 | 260.6872 | 251.6718 |

| 10 | 2 | 150 | a | 388.2158 | 379.0371 | 382.8692 |

| 10 | 3 | 150 | a | 237.7211 | 235.1055 | 228.3656 |

| 10 | 2 | 100 | b | 379.7337 | 376.8501 | 379.9041 |

| 10 | 3 | 100 | b | 254.0586 | 249.6524 | 253.8969 |

| 10 | 2 | 150 | b | 348.0816 | 339.3629 | 345.4822 |

| 10 | 3 | 150 | b | 257.2213 | 251.1654 | 250.7208 |

| 25 | 4 | 150 | a | 643.5016 | 627.7213 | 630.4875 |

| 25 | 3 | 150 | a | 788.5648 | 762.4215 | 768.6529 |

| 25 | 4 | 200 | a | 600.6101 | 591.4878 | 588.1468 |

| 25 | 3 | 200 | a | 762.6971 | 760.5763 | 755.4764 |

| 25 | 4 | 150 | b | 543.3693 | 539.8765 | 541.7146 |

| 25 | 3 | 150 | b | 813.4865 | 807.4245 | 806.1265 |

| 25 | 4 | 200 | b | 520.5971 | 517.9854 | 519.8875 |

| 25 | 3 | 200 | b | 742.7545 | 738.7964 | 730.9854 |

To install all the dependencies, run the following command:

pip install -r requirements.txtThen run interface.py , the following menu will appear:

0 - all

1 - 6 pick-faces, 2 pickers, 60 items capacity, data a

2 - 6 pick-faces, 2 pickers, 90 items capacity, data a

3 - 6 pick-faces, 2 pickers, 60 items capacity, data b

4 - 6 pick-faces, 2 pickers, 90 items capacity, data b

5 - 10 pick-faces, 2 pickers, 100 items capacity, data a

6 - 10 pick-faces, 3 pickers, 100 items capacity, data a

7 - 10 pick-faces, 2 pickers, 150 items capacity, data a

8 - 10 pick-faces, 3 pickers, 150 items capacity, data a

9 - 10 pick-faces, 2 pickers, 100 items capacity, data b

10 - 10 pick-faces, 3 pickers, 100 items capacity, data b

11 - 10 pick-faces, 2 pickers, 150 items capacity, data b

12 - 10 pick-faces, 3 pickers, 150 items capacity, data b

13 - 25 pick-faces, 4 pickers, 150 items capacity, data a

14 - 25 pick-faces, 3 pickers, 150 items capacity, data a

15 - 25 pick-faces, 4 pickers, 200 items capacity, data a

16 - 25 pick-faces, 3 pickers, 200 items capacity, data a

17 - 25 pick-faces, 4 pickers, 150 items capacity, data b

18 - 25 pick-faces, 3 pickers, 150 items capacity, data b

19 - 25 pick-faces, 4 pickers, 200 items capacity, data b

20 - 25 pick-faces, 3 pickers, 200 items capacity, data b

choose config: (0,2..,20). x to exit

note: since the heuristic is compound of computationally hard problems, it's recommended to run the 25 pick faces configurations on a computer with at least 16GB RAM

Choose the configuration by entering it's number (0-20)

The results are looking like:

$@==################################################################################==@$

Vector [2, 7, 1, 1, 3, 0] is packed in bin 5.

Vector [0, 5, 3, 0, 1, 4] is packed in bin 2.

Vector [1, 2, 7, 6, 2, 0] is packed in bin 1.

Vector [0, 0, 0, 1, 5, 1] is packed in bin 1.

Vector [0, 4, 2, 0, 1, 7] is packed in bin 2.

Vector [0, 1, 3, 5, 1, 7] is packed in bin 6.

Vector [4, 8, 6, 1, 7, 7] is packed in bin 2.

Vector [1, 6, 2, 0, 4, 6] is packed in bin 6.

Vector [4, 0, 6, 7, 0, 6] is packed in bin 6.

Vector [8, 7, 1, 2, 0, 7] is packed in bin 11.

Vector [5, 5, 0, 7, 0, 6] is packed in bin 5.

Vector [1, 1, 0, 5, 0, 1] is packed in bin 1.

Vector [7, 4, 1, 2, 2, 0] is packed in bin 1.

Vector [0, 5, 4, 0, 0, 2] is packed in bin 1.

Vector [0, 0, 8, 1, 3, 5] is packed in bin 13.

Vector [8, 2, 4, 0, 7, 5] is packed in bin 13.

Vector [2, 2, 3, 3, 1, 6] is packed in bin 13.

Vector [1, 5, 0, 2, 0, 0] is packed in bin 11.

Vector [5, 6, 0, 4, 0, 5] is packed in bin 5.

Vector [8, 6, 2, 3, 7, 1] is packed in bin 11.

bin 1: [ 9 12 12 14 9 4]

bin 2: [ 4 17 11 1 9 18]

bin 5: [12 18 1 12 3 11]

bin 6: [ 5 7 11 12 5 19]

bin 11: [17 18 3 7 7 8]

bin 13: [10 4 15 4 11 16]

batch 0: [ 9 12 12 14 9 4] sum: 60

batch 1: [12 18 1 12 3 11] sum: 57

batch 2: [17 18 3 7 7 8] sum: 60

batch 3: [ 4 17 11 1 9 18] sum: 60

batch 4: [10 4 15 4 11 16] sum: 60

batch 5: [ 5 7 11 12 5 19] sum: 59

$@==#### 6 pick-faces, 2 pickers, 60 items capacity, data a -> 93.8078 seconds.####==@$

$@==################################################################################==@$

- The lines which starts with Vector says to which bin (batch) each order related. the bins id can take different numbers, they mean nothing at that stage.

- The lines which starts with bin represents the actual batches and the number of items that should be picked on each pick face.

- The lines which starts with batch are ordered.

- The last line describes the configuration and the result of the simulation.