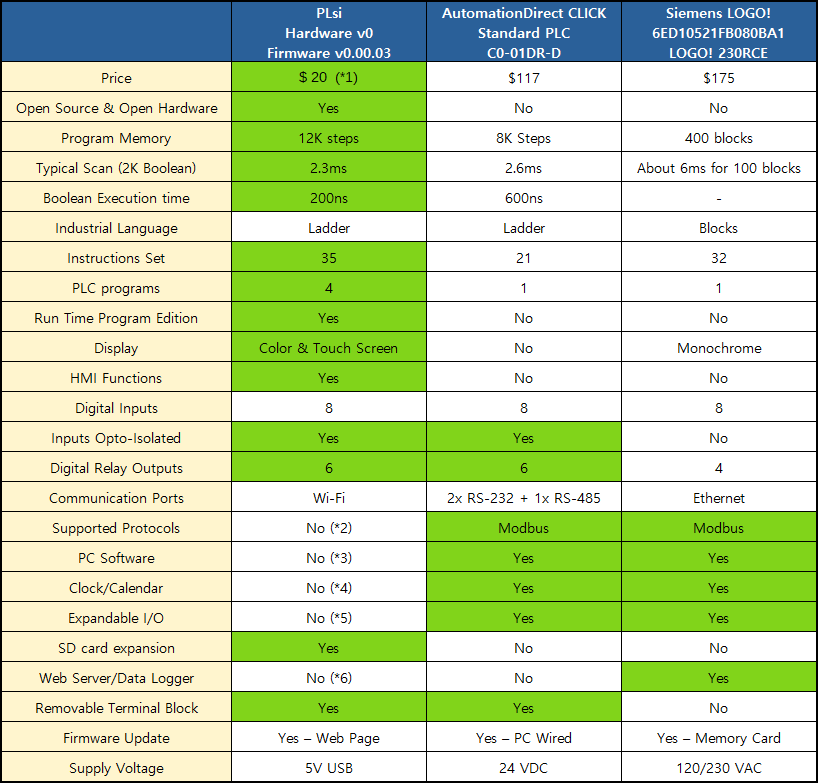

Create a PLC & HMI with the following main characteristics:

- To not require external systems such us Laptops or Cellphones to be programmed

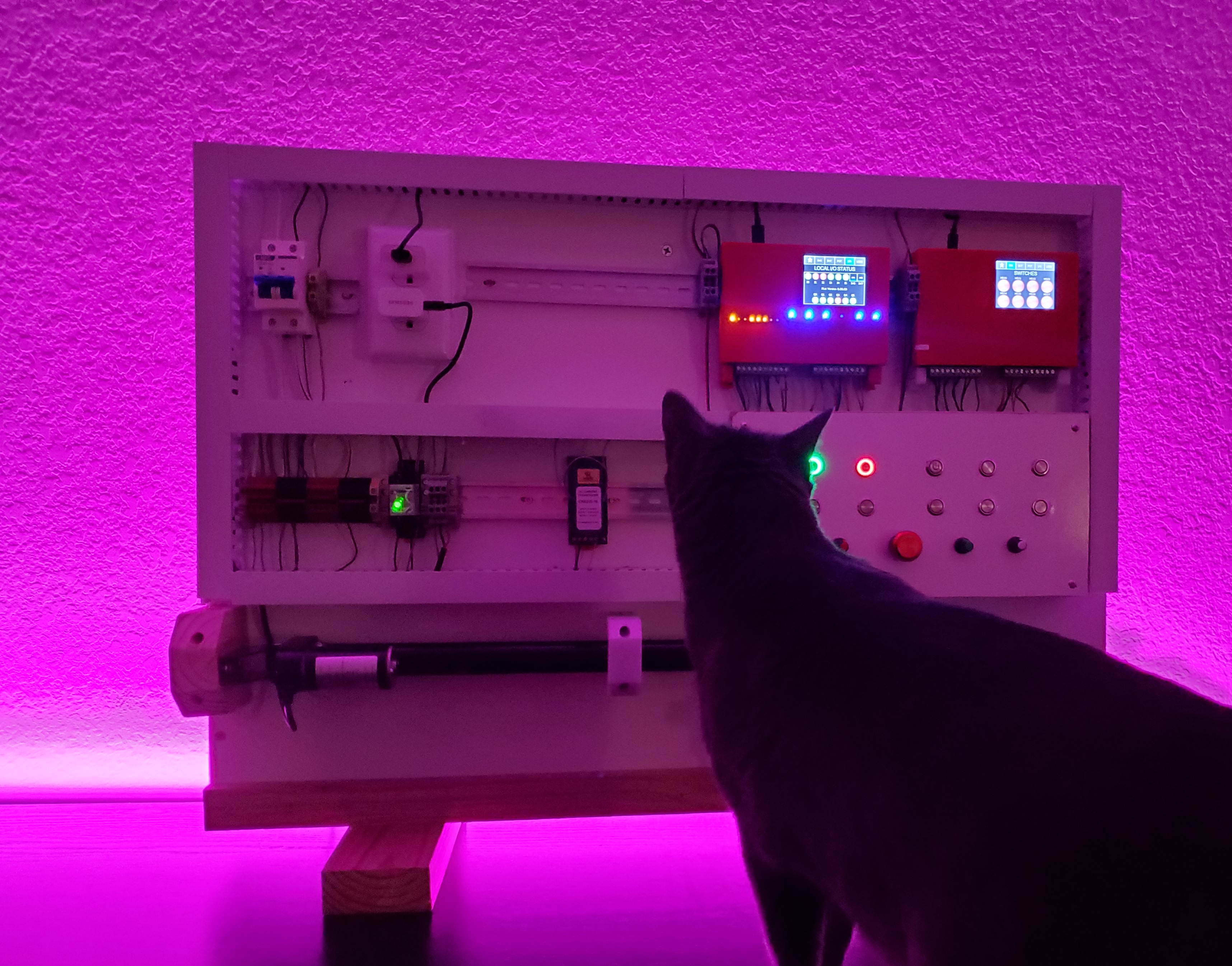

- To be used on Classroom for educational purposes, IoT applications or industrial low risk applications

- Software and Hardware with Industrial performance and features

- Forever Open Source and Open Hardware

- Focus on Low Cost, V0 hardware estimated in less than $20

Main characteristics:

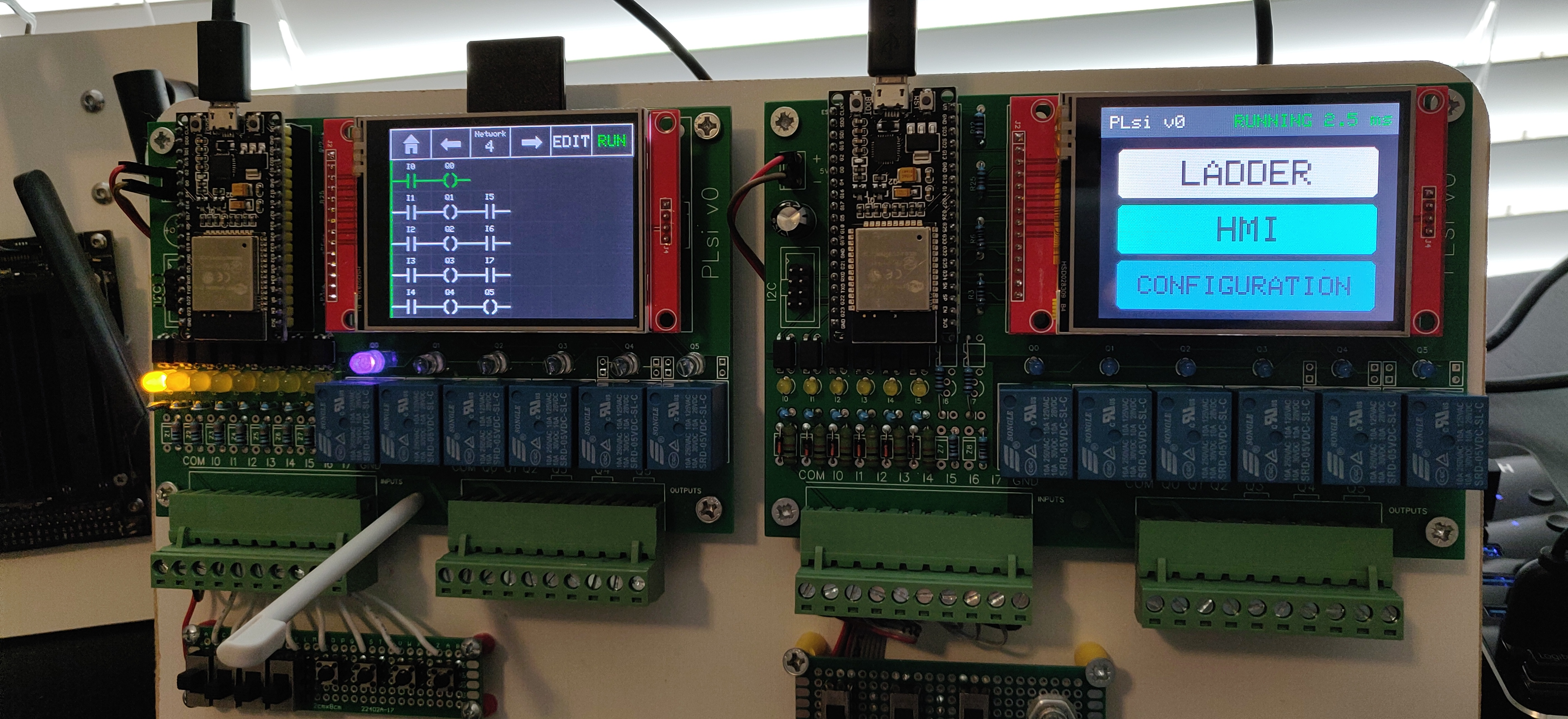

- Easy to build, no SMD components. DIY!

- ESP32 Processor

- Dual Core @240MHZ

- Wi-Fi connectivity

- 2.8" 320x240 Touchscreen Display

- 8 Hardware Inputs 5-24VDC Isolated with status led

- 6 Hardware Relay Outputs with status led. Max 10A, external fuse required

- Different combinations of Digital and Analog I/O using the same board

- Analog I/O range: 0-5V

- Removable Terminal blocks

- USB 5Vdc main power supply

- I2C port for hardwired expansions

- SD Card slot

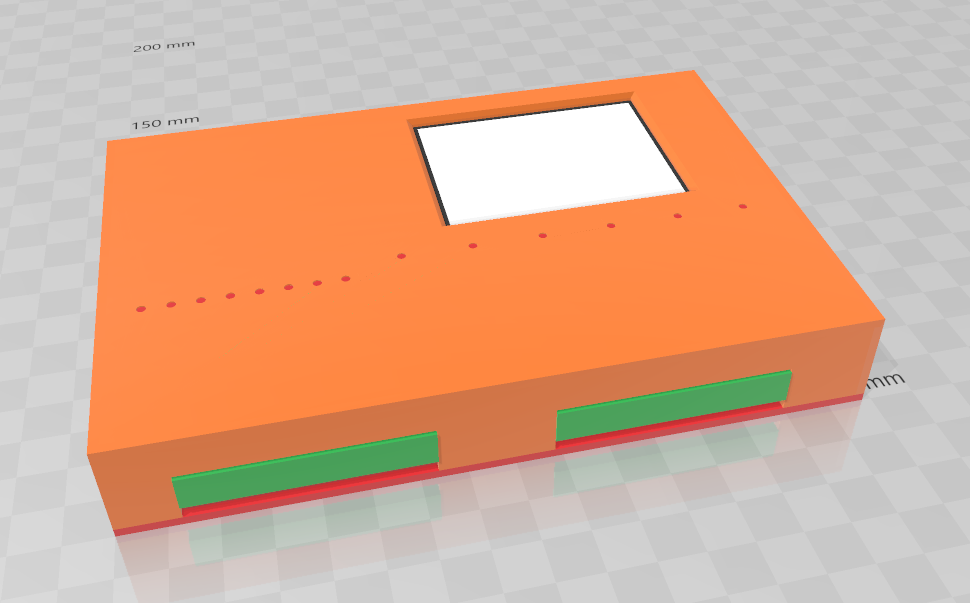

- 3D printed housing model including DIN rail mounting bracket

Main functionalities:

- PLC Ladder Logic Instruction set:

- 35 instructions

- Boolean instructions full set

- Timers and Counters full set

- Comparisons full set

- 16 bit math functions

- PLC Memory Areas:

- 2000 Marks (M)

- 200 Counters (C)

- 300 Timers (T)

- 10000 Registers 16bits (D)

- PLC Program size:

- Up to 400 networks of 6x5 cells (12K boolean instructions)

- Up to 4 PLC programs stored on internal memory (max. 400 networks each)

- PLC Program Editor

- Online Edition (with PLC running)

- Row, Column and Network Editor

- Network Navigation

- PLC performance and control

- Scan time of 2.3ms for 2000 Boolean instructions

- Processor Core 1 runs Ladder Logic exclusively

- RUN/STOP with user confirmation

- Display functions:

- PLC Programming and debugging

- PLsi Configuration

- HMI

- "Fix" version implemented (User cannot edit memory areas nor texts)

- Screen 1: 8 Switches M500 to M507

- Screen 2: 8 Buttons M510 to M517

- Screen 3: 8 User Input Values D500 to D507

- Screen 4: Local I/O visualization

- Screen 5: 8 Indicators M520 to M527

- Communications:

- Wi-Fi configuration. Only DHCP

- SSID scanning functionality

- Firmware update via Web Page

- Analog Inputs and Outputs

- Selectable via Configuration page

Build your own unit: PLsi v0 Hardware Manual

Wiring, configuration and programming: PLsi v0 User Manual (on contruction)

- DIY components pricing is included here

- This pricing considers to purchase some bulk quantities

- Two industrial protocols are planned to be added in future releases

- Not planned yet

- To be included on Hardware V1 Issue #35

- The I2C expansion port is available to connect wired expansions

- Wi-Fi expansion modules are also feasible

- Not in the roadmap yet

- A Web HMI hosted on the PLsi unit is proposed on Issue #42

The PLsi board v0 is designed to support, at least, 2 different configurations:

- All Digital I/O

- 8 Digital Inputs

- 6 Digital Relay Outputs

- Digital and Analog I/O

- 6 Digital Inputs

- 4 Digital Relay Outputs

- 2 Analog Inputs 0-5V

- 2 Analog Outputs 0-5V

Check the drawing and the Hardware Manual for more details on how to build the 2 different models using the same board

- Supply Voltage: 5V 1A (recommended 2A)

- Standard Micro USB type B connector

- External fuse or fuses are required to protect the Outputs circuits

- Fuse size has to be calculated considering a total MAX consumtion of 10A

- SD Card is optional, it has no functionality implemented in Fimware v0.00.03

- I2C Port is optional, it has no functionality implemented in Fimware v0.00.03

- Analog Inputs and Outputs are not isolated

Teach yourself and others how to program a PLC :)