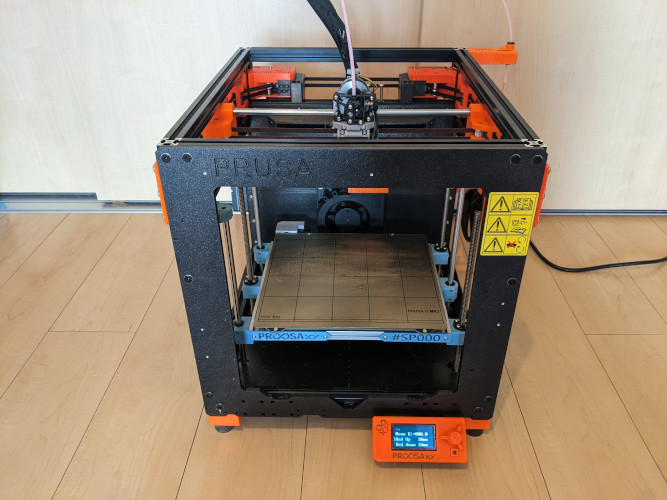

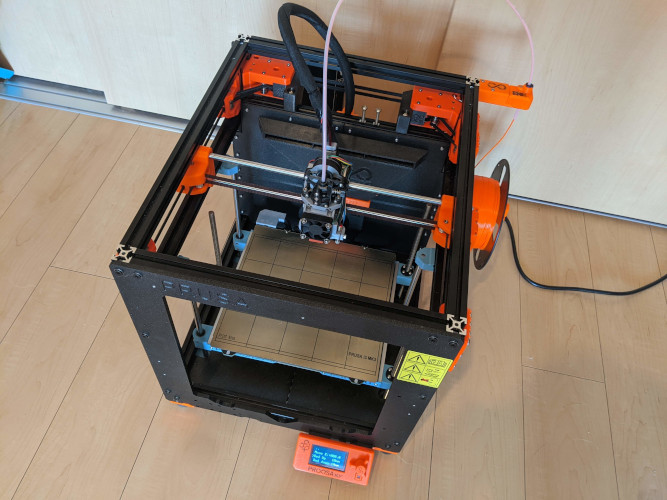

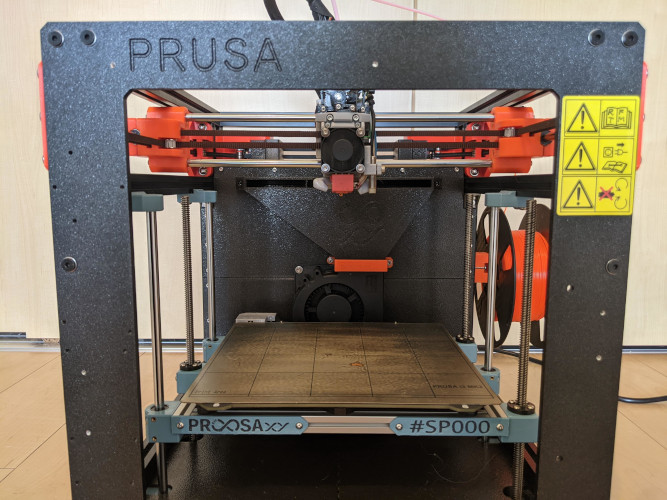

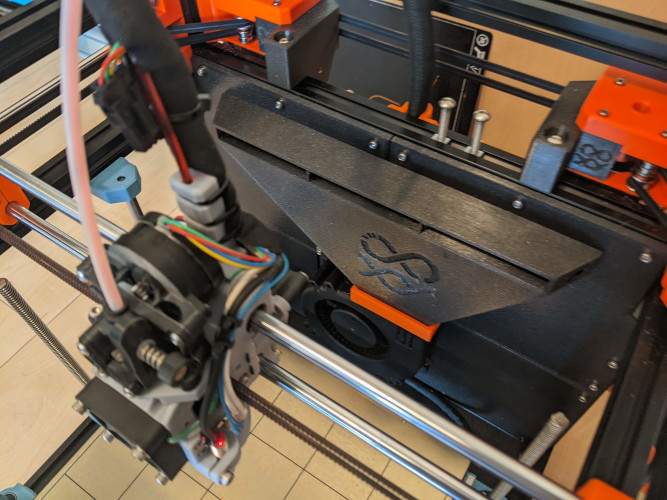

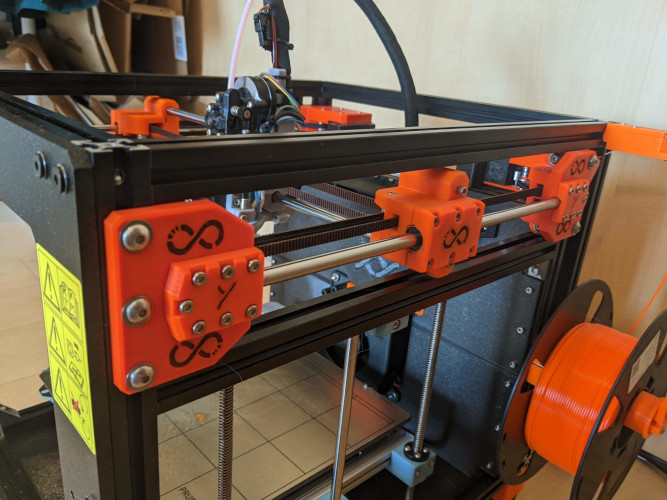

CoreXY conversion for Prusa MK3/S. This build is aiming at getting more performance out of your 6 years old machine with the lowest cost possible by re-using most the MK3/S stock parts.

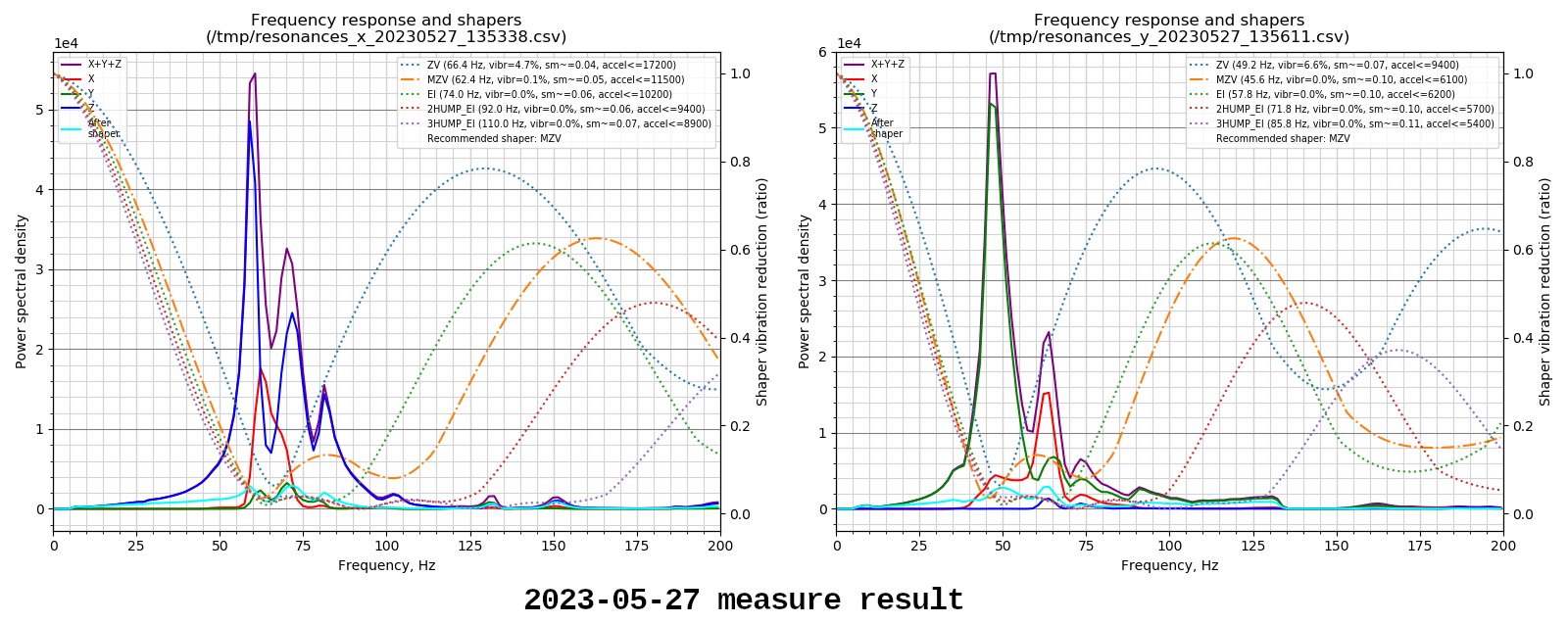

- Better performance (check input-shaper graph bellow)

- Semi-enclosure by default. Panels mount and top hat parts will be added later.

Dual z axis(default) or independent tripple Z axis(Optional)Triple Z (independent or sync based on controller board) by default or dual Z(optional)- Single v6 hotend(default) or mixed 2-in-1-out hotend(WIP)

- Optional AUX cooling fan

- Our industrial leading SnakeOil technology

- All the main parts design are completed. Test print result are posted in our Discord server

- All part STLs are exported.

- Full BOM added 2023/07/11

- I'm working on a simple build log/manual.

- For updates, please visit our Discord server

- The input-shaper calibration is quite good for an 8mm shaft machine, in my opinion. We have a recommended acceleration of about 6000 mm/s2 (which should be used as the limit for outer perimeter acceleration), and a higher maximum acceleration/speed, depending on how fast your motor can run.

- For some extra speed boost, check my slicer plugin (klipper firmware only)

- This mod requires some drilling on the original frame, cutting the original motor leadscrew, and linear shafts. This drilling/cutting is easy enough to be done with a hand drill and a hacksaw BUT THERE IS NO WAY BACK. You won't be able to convert back to the original MK3/s machine if you change your mind later.

- Some small changes/patches might be needed after I have more test data and feedback..

- To keep the cost down and reuse old components, there are some trade-offs I made:

- The machine is semi-enclosed by default and will need some printed panels and a top hats to fully enclose it.

- To match the frame height, cutting the motor leadscrew and linear shafts is required.

| Mk4 bonker benchy | Real-world print | |

|---|---|---|

| Video |

|

|

| Description | I use the setting Prusa used on their mk4 12 mins benchy with accel pump up a little. Print result (images)  |

|

This printer design use the following parts from other opensource project:

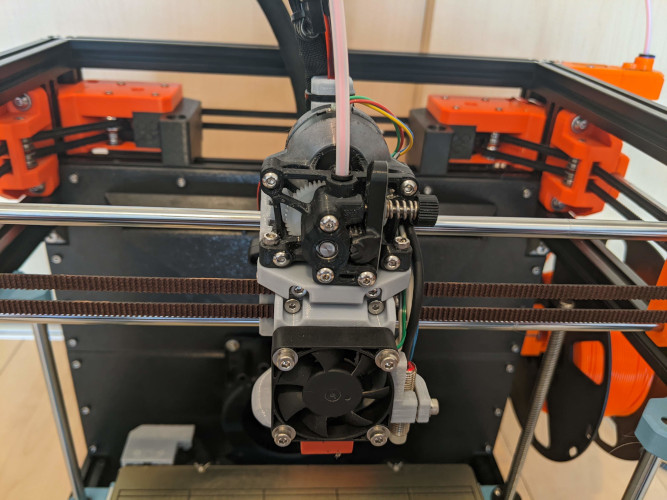

- Fan duct from EVA 2.3

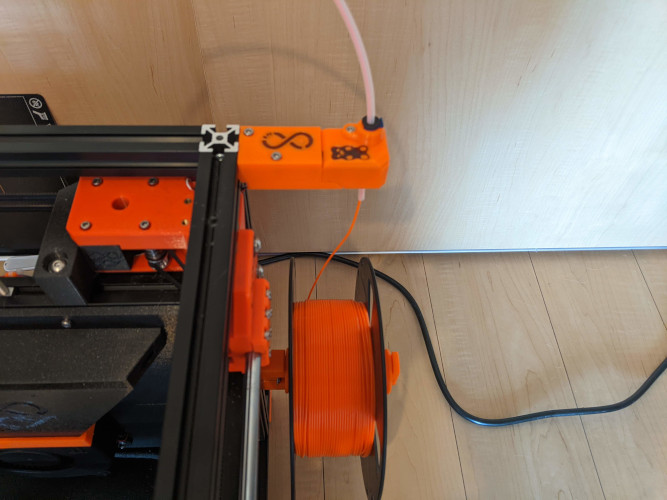

- Filament sensor from Bear Extruder And X Axis (BearExxa)

- Sherpa mini extruder from Annex Engineering

- Original hardware from Prusa MK3

- Sherpa mini extruder is an original work of Annex Engineering, modified parts using their source code/design files are re-released under ANNEX Engineering License.

- EVA2 is an original work of EVA-3D, modified parts using their source code/design files are re-released under GNU General Public License v3.0

- Bear Extruder And X Axis (BearExxa) is an original work of Grégoire Saunier, modified parts using their source code/design files are re-released under GNU General Public License v3.0

- Prusa MK3 is an original work of Prusa3D, modified parts using their source code/design files are re-released under GNU General Public License v2.0

- This printer design(ProosaXY), it's document and software are released under GNU General Public License v3.0