If you have questions or wanna stay more up to date with Monolith, consider joining the dedicated Discord server.

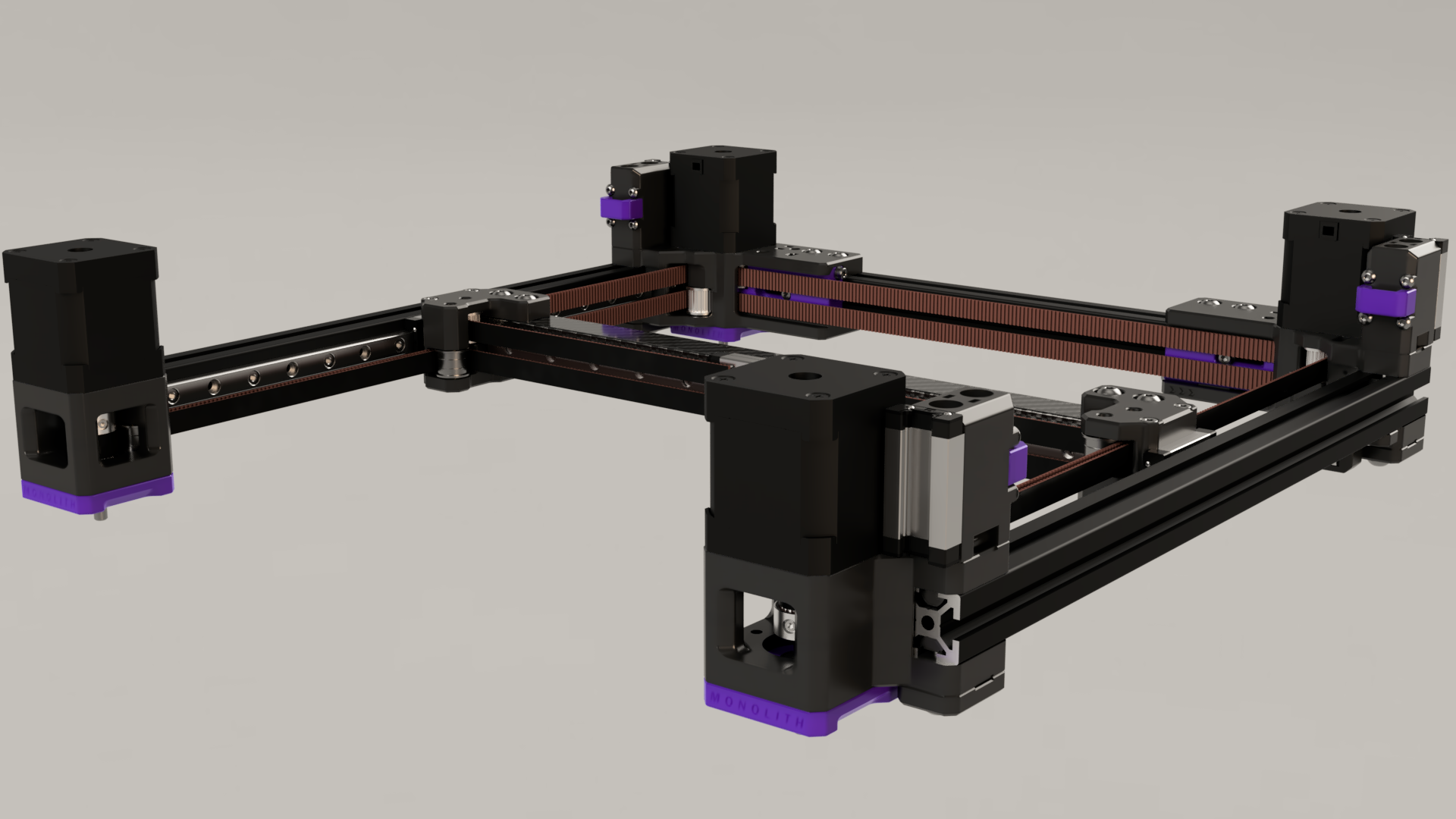

This is a performance-oriented, configurable gantry platform for Voron 2.4 and Trident.

Available drive configurations:

- 2WD

- AWD

Available belt widths:

- 6mm

- 9mm

Available X-axis configurations:

- Front rail (flipped belts, toothed side facing the X extrusion = limited toolhead compatibility)

- printed and metal versions

- toothed idler delete (drive pulleys with live shafts last longer and they're easier to source with 16mm OD)

- significant effective tensioner range increase (50% or more)

- optional zero protrusion mode (no extra panel spacing, but similar build volume loss to other AWDs) without changing the gantry parts

- The shortest and the simplest belt path possible without losing full bed capability even with AWD (toolhead dependant)

- AWD without increasing belt length and idler count

- Double shear support

- Increased printed part rigidity

- Uncluttered design

- Cheap BOM

2WD: Due to the 10-15cm shorter belt path, stiffer and lighter XY joints (inside Y rails) your printer should perform similarly to a 50mm smaller one equipped with the same toolhead and X axis setup.

AWD: It doesn't come at the cost of adding 20cm extra belt length and more idlers, so input shaper scaling should be close to +100% vs 2WD due to the truly halved effective belt length. IF there are no rigidity bottlekecks elsewhere, which is rarely the case.

- There's limited toolhead support currently because of the flipped belt path. Voron-compatible toolheads that have loop-around belt clips will work, but you WILL lose the ability to tuck away the excess belt.

- You have to space out the front (AWD only) and rear panels on your printer by at least 5mm (Monolith Panels) or have a 4040 frame.

- The tensioner range is less than half compared to stock. Monolith is not recommended for larger than 350mm build volume.

- Z chain relocation/delete on V2

- Trident rear vertical extrusion brackets have to be rotated by 180 degrees

- Recommended print settings: 4 walls, 40% infill (or more), 0.2mm layer height, 0.4mm nozzle

- Recommended material for 6mm versions: ABS or better

- Recommended material for 9mm versions: ABS CF or better

- backwards comppatible

- less confusing showroom style CAD to aid assembly and help with integration

- top rail versions are now phased out, removed the mirrored CD parts (simplified BOM)

- double shear bearing support is now standard and possible with short shafted motors on 6mm 2WD and 6mm V2 AWD configs (6mm tensioner body reprint is needed to gain clearance) Trident 6mm AWD will need at least one long shafted stepper to clear the left front leadscrew.

- XY joints now have the double screw side on top by default for better X endstop support, but they still can be flipped to gain clearance for low extruder motors

- all versions have the Y endstop on the right by default

- top motors and top Z joints are preferred where possible (less heat from the bed, better frame bracing options under the Z rails on V2)

- tweaked pin lengths for a more uniform look, no M3 standoffs in the BOM (all previous BOM hardware remains usable)

This work is licensed under a

Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.