Carriage stop/emergency switch?

javaduke opened this issue · comments

I'm thinking about making a custom carriage stop with a switch that will cut the servo power off when engaged by the carriage.

This can essentially be a poor man's thread/cut to shoulder feature - I would simply set a carriage stop at the predefined location and then the cutter would stop at this location even though the power feed or lead screw is still engaged.

Wondering if anyone can think of any possible downsides of this approach? And what would be the best place in the circuits to include this switch? I can simply cut the power line to the servo and insert the switch there, or is there a better place?

The problem with that is you'll lose sync between the carriage position and the spindle since the carriage will stop but the spindle wont...

Have a look at the thread to shoulder code I added - it's cheaper than a switch... ;)

https://github.com/kwackers/electronic-leadscrew

I made a carrige stop and an emergency stop on my lathe, not for threading but fot safty and turning to a rough shoulder. It works very well for that purpose. all you need to do is interupt the enable circuit with a normaly closed switch. works well. I have a micro switch built into a clamp that can slide along the way then the carrige trigers the micro switch.

.. what if you cut the encoder signal?

As I mentioned I cut the enable wire going to the servo, this stops the motor quickly. It will stop every time within .002 of the shoulder. I ran my micro switch and an emergency stop in series. makes for an easy stop. Im not sure about the encoder although i would think if you cut the 5 volt signal wire to the encoder it would also stop the servo.

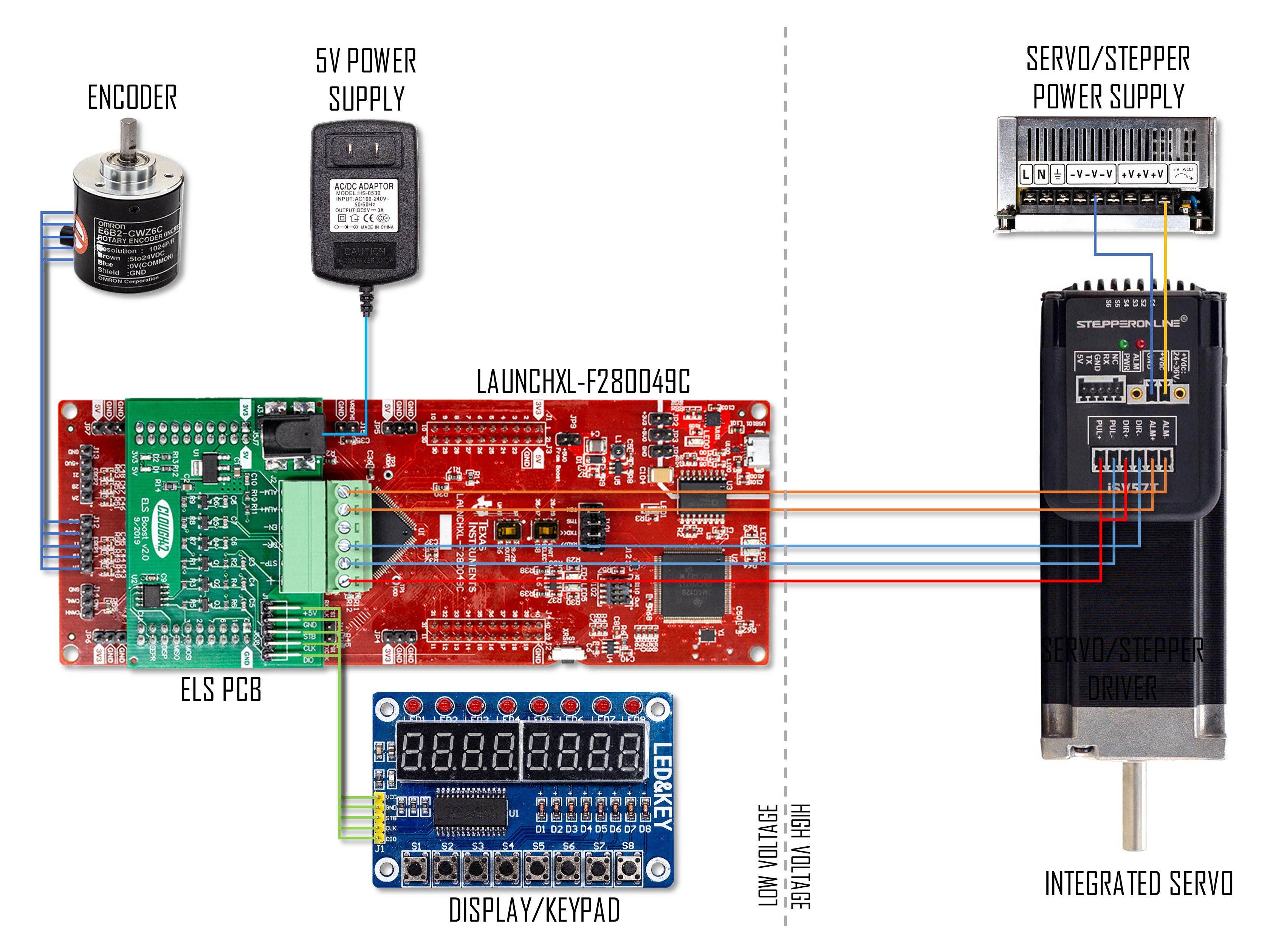

Which one is the enable wire on that diagram? I see PUL, DIR and ALM, which one I should cut?

The servo in the picture dont have enable signal.. so you cant use that..

Direction wire wont do it so try the pull wire, just disconnect it at the els board and see what happens. If it doesnt stop it try the red + wire that should stop the servo.